If the filament is not loaded into the extruder, yet the printer is trying to pull the filament inside, there might be a hardware problem in some of the extruder components: we will examine the causes and fixes in this article.

Filament tip

Ensure that the filament tip is cut at an approximate 45 degrees angle. The printer might struggle to load filament otherwise.

Retry procedure

After an attempt at loading filament, the printer will prompt a screen, where it is asked if the filament color is correct. If the filament is not oozing from the nozzle at this stage, push the filament towards the extruder, and after that, select "retry".

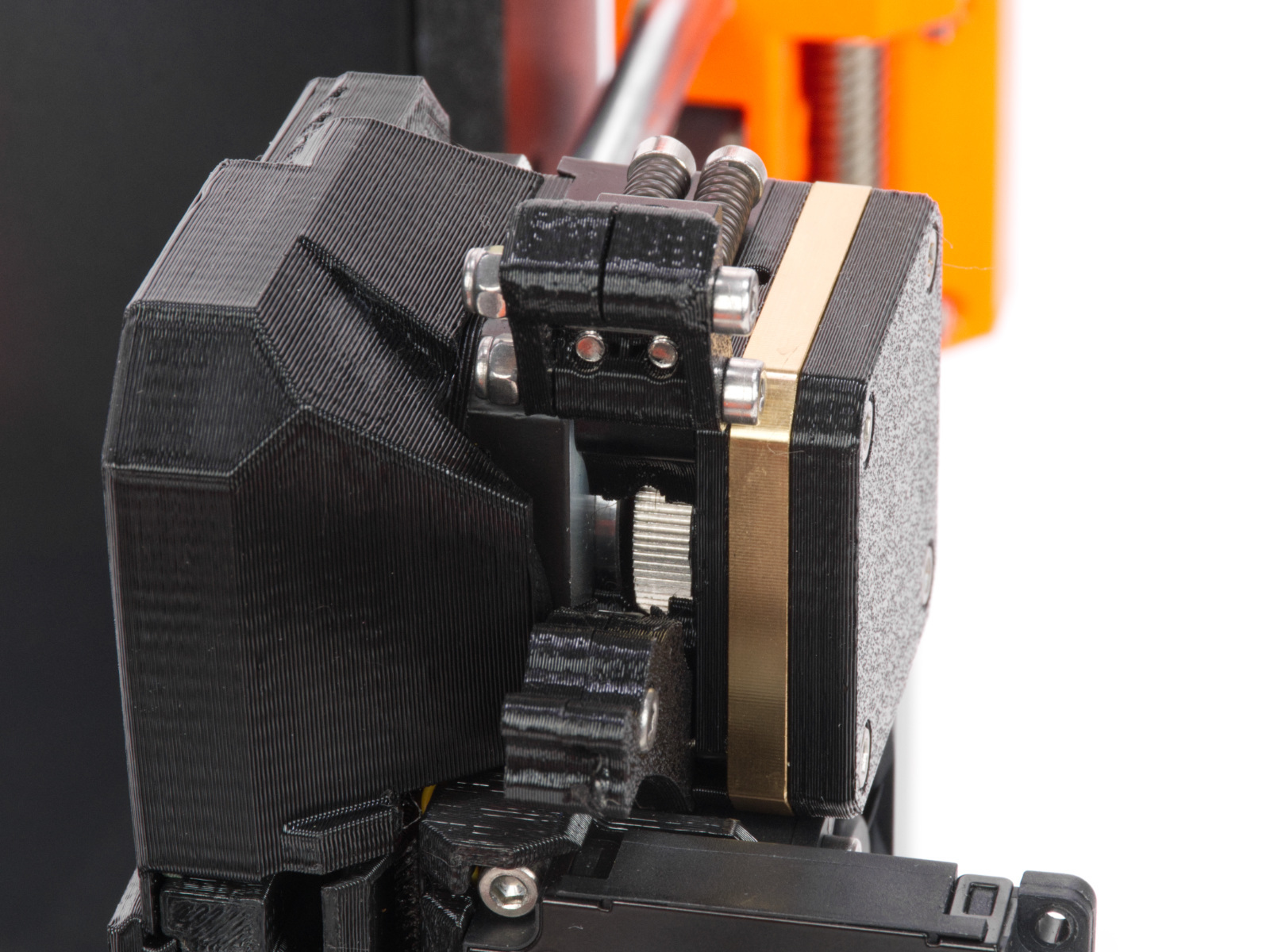

Idler tension screws

The extruder includes two idler tension screws, to set the correct distance between the drive gear and the two driven gears. These are set to the optimal position at the factory. In case of an intervention on that component, it will be necessary to adjust the idler tension screws to their optimal position: the tips of the screws must be aligned with the front surface of the Idler Nut. After that, close the Idler Block.

Clogged hotend

Follow the instructions on the dedicated article on how to spot and fix a clogged hotend.

4 comments

However, when I use “cleaning filament”, everything looks completely normal. Filament comes out of the nozzle; cleaning or extruding works properly. Filament can also be unloaded.

The printer has been in service for about 4 months and primarily printing PETg.