A clogged nozzle or hotend is a common issue for FFF/FDM printers. If there are no issues, the filament is pushed in the hotend, melted, and then extruded through the nozzle. However, if the nozzle is damaged or there are impurities in the filament it might get stuck in the hotend, clogging the printer.

Visual check

- Is the filament reaching the nozzle? Check if the filament goes past the Nextruder gear.

- Is the filament coming out of the nozzle? Pay attention when loading the filament.

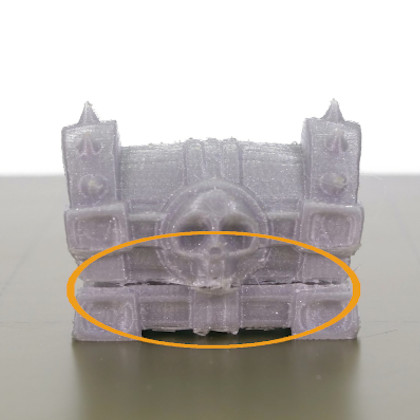

- Partial clog - gaps and missing layers

- Partial clog - filament curling up and sticking to the nozzle

Soundcheck

Check if there are clicking noises from the extruder

- If there is a loud clicking noise, this most likely suggests the nozzle is clogged or deformed

- If there is a light clicking noise, this can most likely point to the gearing

Partial clog

Sometimes the clog is partial, meaning that the printer is able to push some filament through, but it is not enough to print the object properly, leading to visible gaps and missing layers. An early sign of a clogged nozzle is that the filament is not extruded consistently, curls up, and sticks to the nozzle.

Extruder clicking

The hotend or the nozzle is partially or fully clogged and the internal resistance against the flow of the filament is greater than what the gears are able to push. As a result, the gears are skipping leading to the “clicking” noise and in most scenarios also to the grinding of the filament.

Choosing the right method depends on whether you are able to at least partially load/unload the filament or whether the printer is fully jammed and refusing the move the filament even a little.

Before you start fixing the printer, try unloading the filament and removing it completely. If you are unable to do it, it might indicate a more serious problem, but we will deal with this one as well.

Also, move the heatbed downwards from LCD Menu - Control - Move Axis - Z-axis or by long-pressing the control knob, this way you will get better access to the parts that are clogged.

Extruder idler screws

The extruder includes two idler tension screws, to set the correct distance between the drive gear and the two driven gears. These are set to the optimal position at the factory. In case of an intervention on that part, you can adjust the idler tension screws to their optimal position: the tips of the screws must be aligned with the front surface of the Idler Nut. After that, close the Idler Block.

Gears

Over time, a deposit of filament debris can form in the grooves of the feeding gear, which then causes insufficient filament extrusion. Access the extruder by lifting the Idler Nut, and then moving the Idle Shaft. You can blow away the dirt with compressed air, or use a brass brush or an ordinary toothpick. Use the access hole on the side of the extruder.

Nozzle

- Heat the nozzle to the appropriate temperature according to the filament material you will be printing from. First, introduce the filament, then insert an acupuncture needle (included in the package) or a thin wire (0.3-0.35 mm) into the nozzle from below to a depth of approximately 1-2 cm. Use protective gloves if material suddenly starts to flow from the nozzle.

- Select the Load Filament option from the LCD menu and check that the nozzle is actually pushing the filament.

- Insert the wire or acupuncture needle into the nozzle again and repeat the whole procedure several times. If the filament is extruded correctly, the nozzle is clean.