The Induction auto-leveling sensor is a vital component facilitating the calibration of the MINI and MINI+. It acts like the Z end-stop and is the main component in mesh-bed leveling. You may have either:

- SuperPINDA: Stands for Super Prusa INDuction Autoleveling sensor, introduced with the MINI+ upgrade.

- M.I.N.D.A.: Stands for Mini INDuction Autoleveling sensor.

How it works

Starting from firmware 4.3.0, the MINI has the option to see the readings of the M.I.N.D.A./SuperPINDA on the printer's display. Go to Info -> Sensor info, and you will see the M.I.N.D.A./SuperPINDA status. Note that the menu will always have M.I.N.D.A. written, even if you have the SuperPINDA.

For safety reasons, the M.I.N.D.A./SuperPINDA will always trigger "1" if disconnected, to prevent it from crashing the nozzle into the bed, should it fail. Therefore it is a telltale sign of a fault if the Z-axis will move upwards during the mesh bed leveling or homing, sometimes going up for a couple of points, then lower back down. This happens as the M.I.N.D.A./SuperPINDA loses connection when the print head is in certain positions due to a small break in the wire.

How to test

Firstly, we need to check if the M.I.N.D.A./SuperPINDA sensor works at all. For this test, you need a small and thin metal object (spatula, screwdriver, pliers).

- Raise the Z-axis about 10 cm above the bed to keep it away from any metal.

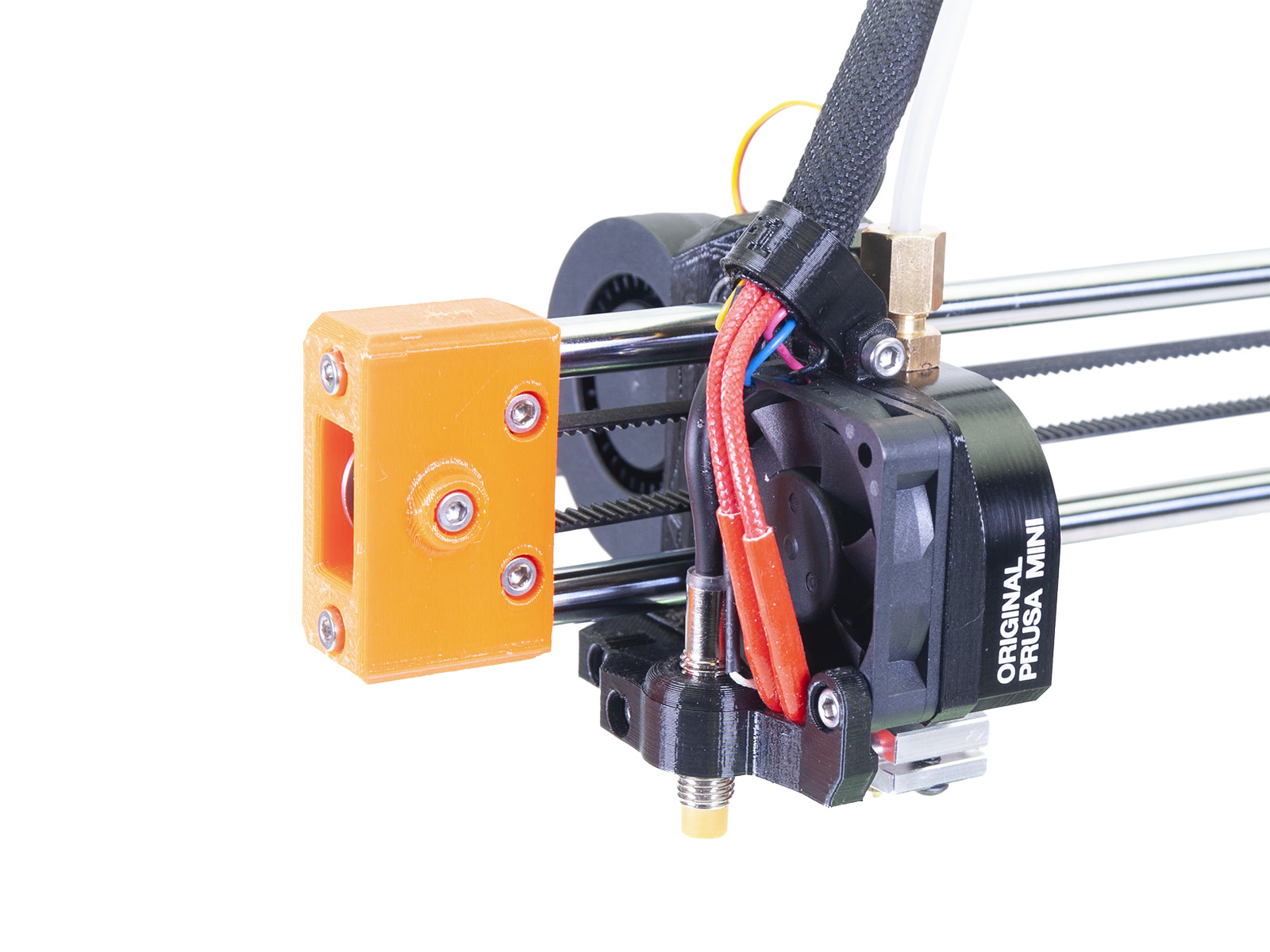

- In the printer's menu, go to Info -> Sensor Info, and see if the M.I.N.D.A. value is 0, and the red light coming out on top of the M.I.N.D.A. is ON.

- Place a metal object below the M.I.N.D.A./SuperPINDA. The status on the menu should turn to 1, and the light on top of the sensor should go OFF.

- While the metal object is below the M.I.N.D.A./SuperPINDA, move the X-axis from side to side and wiggle the cable wrap, and see if the light remains OFF constantly and the status at 1. Any flickering would indicate a fault in the M.I.N.D.A./SuperPINDA sensor.

|  |

| Lit LED | LED not lit, in the presence of metal |

1 comment

Be careful, even if the SuperPINDA works correctly maybe its position is bad. Check if its too far from the nozzle!

Mine was working well BUT it wasn't positioned correctly, it was too far from the nozzle (the little gold piece which heats up), so I think z-axis wasn't doing the whole path (the sensor was detecting the bed too fast) . I aligned the sensor with the nozzle (it's easy) and the Z axis test passed!