If your Original Prusa Multi Material idler barrel has some issues moving, makes clicking noises, or gives the error #04125 Idler cannot home, something is preventing the full movement of the idler barrel.

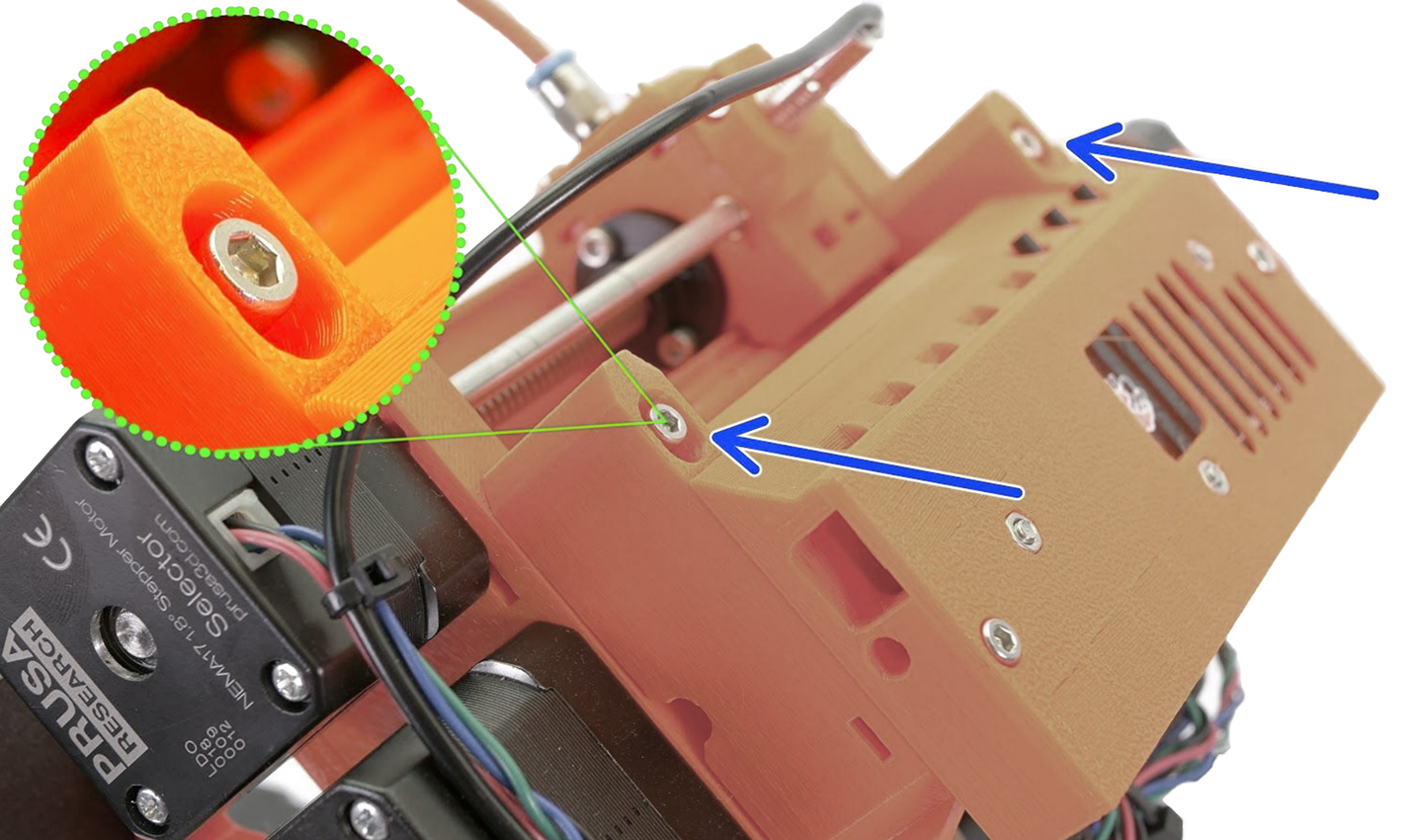

Loosen idler cover

First, check the idler screws' tightness. Too much tension can prevent the motor from turning the idler barrel. You can try completely loosening the tension screws, and allow the MMU to finish the homing. If it passes, then the idler cover is too tight.

To find the perfect tension, tighten the screw about 0.1 mm to 0.4 mm under the edge of the hole on both sides of the idler body. All 5 filaments have to be loaded to the hobbed pulleys position. Then move with the selector to the far right (5th filament position) and back and observe. If you hear clicking, loosen the screws a bit and try to move with the selector again until there is no more clicking.

Check the idler barrel path

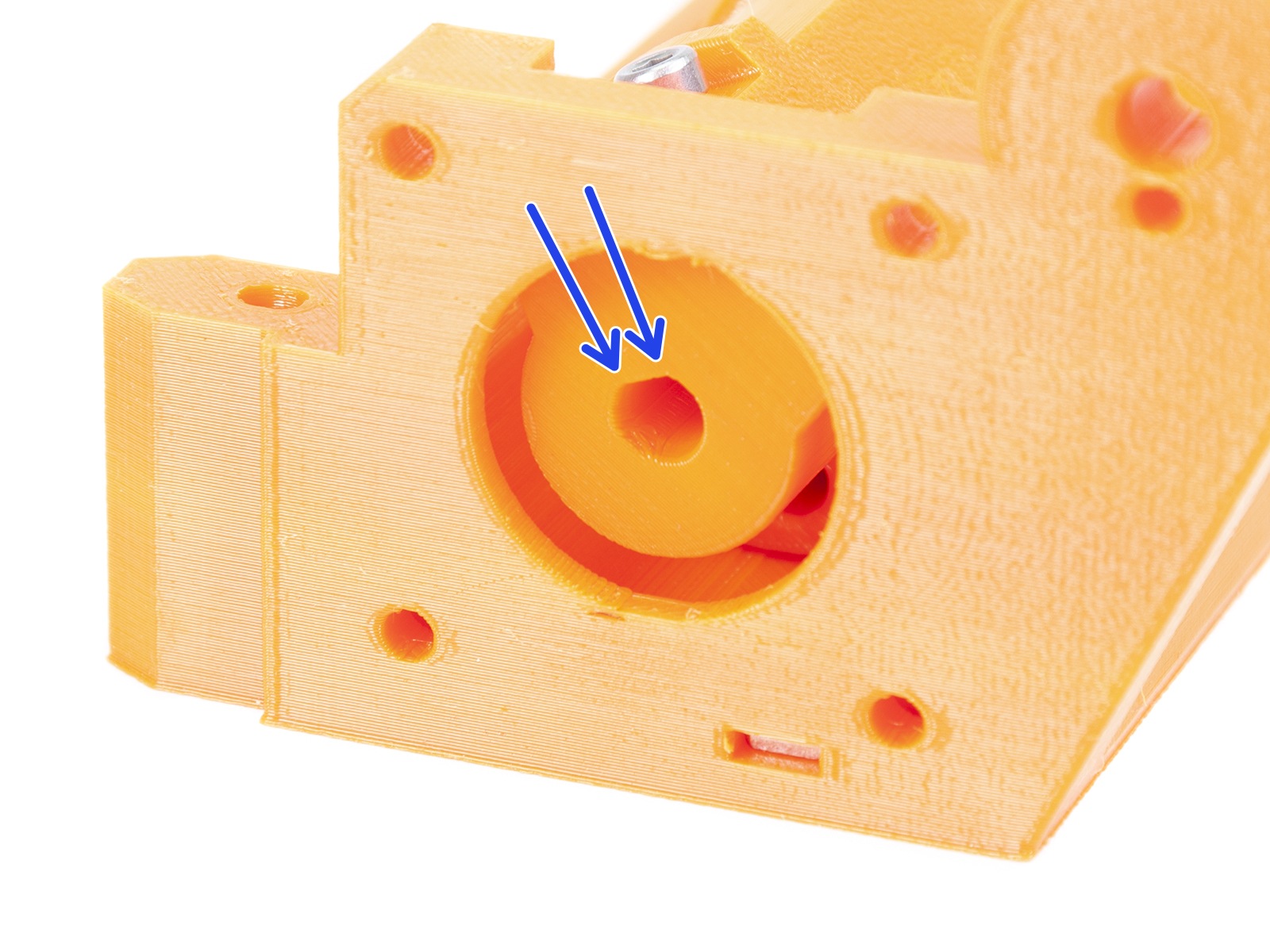

If the idler does not rotate freely with the spring screws loosened, you can open the idler completely and verify that nothing's blocking it, like the remains of filament or dirt. Check if the idler is centered and if the edges of the idler don’t grind the idler body.

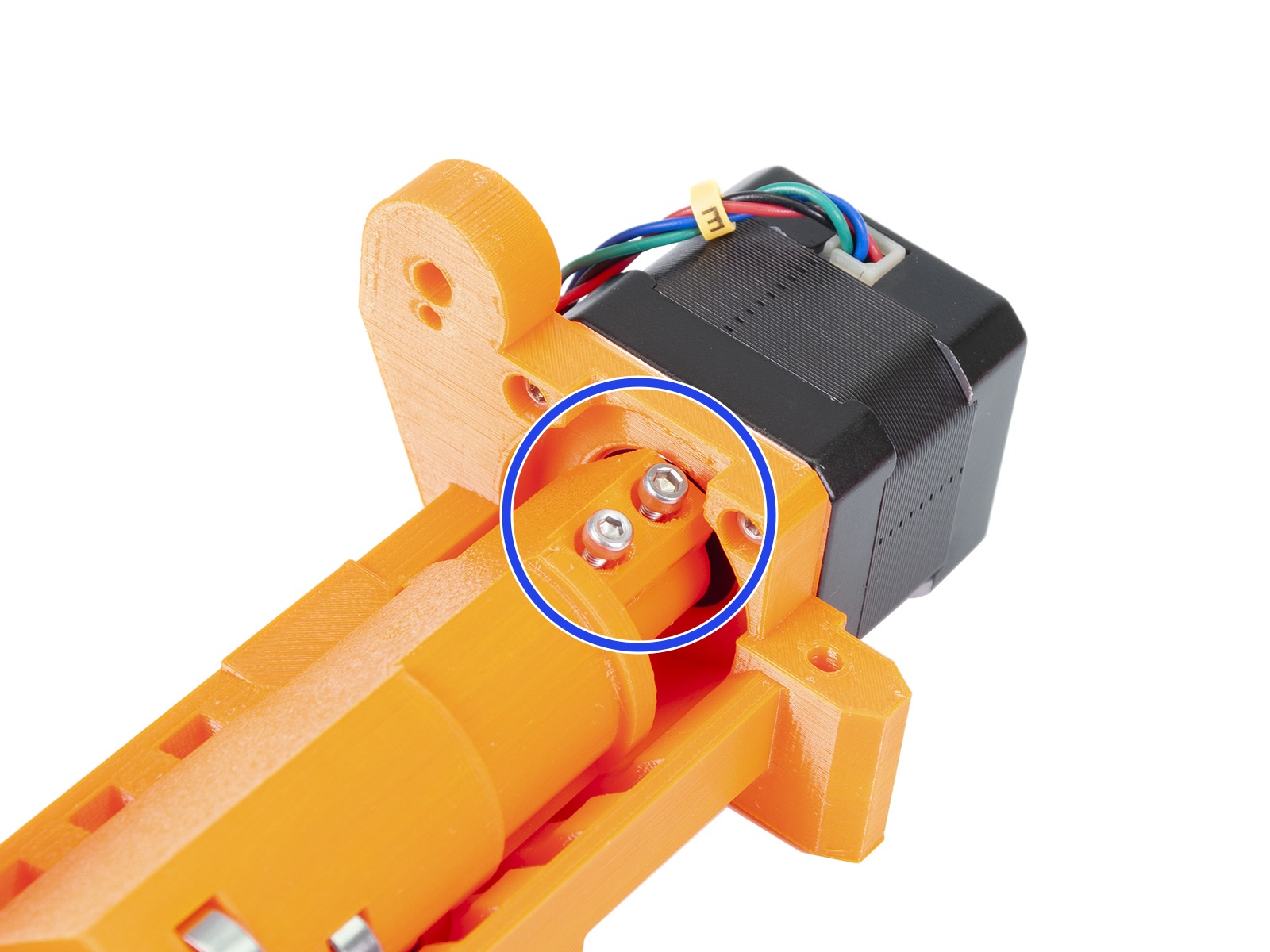

Check the idler barrel connection with the Idler motor. The plastic around the motor shaft cannot be broken or worn out, which can happen due to heat. Move the barrel across the whole axis by hand, and make sure that during the whole range of rotation, the barrel does not touch the cover and does not scratch against the sides.

If the barrel is bent in relation to the rest of the idler, try loosening the two screws that connect it to the Idler motor, and tighten them again gently. Make sure that the two screws are tightened evenly against the flat part of the motor shaft.

|  |

Change Stallguard threshold

If you are getting the #04125 Idler cannot home error, the printer will give you two options. You can either click to Retry or Tune. If the issue is persistent even though you checked all the items above, you can lower the Stallguard value. If the threshold is too high the MMU will not home. Therefore, start from the default value of 7, and decrease the value by 1.

9 comments

The whole time the MMU2 was buzzing at me and giving me the #04125 error. So I disabled the MMU until I figured out the MK3S+ problem, and then the #04125 error went away when I changed this sensitivity setting from 7 to 6. Wasted a whole night figuring this out instead of getting back into 3D printing... Oh well :)