The multi-tool manual calibration for the multi-tool versions of the Original Prusa XL can be done to ensure that the Tool Offset Calibration worked correctly and to fine-tune the offset for each tool. This calibration is also recommended after a nozzle crash, or if a custom nozzle is in use. We prepared a specific test GCode for the dual-head and five-head versions, designed to cover offset errors up to +/-1mm.

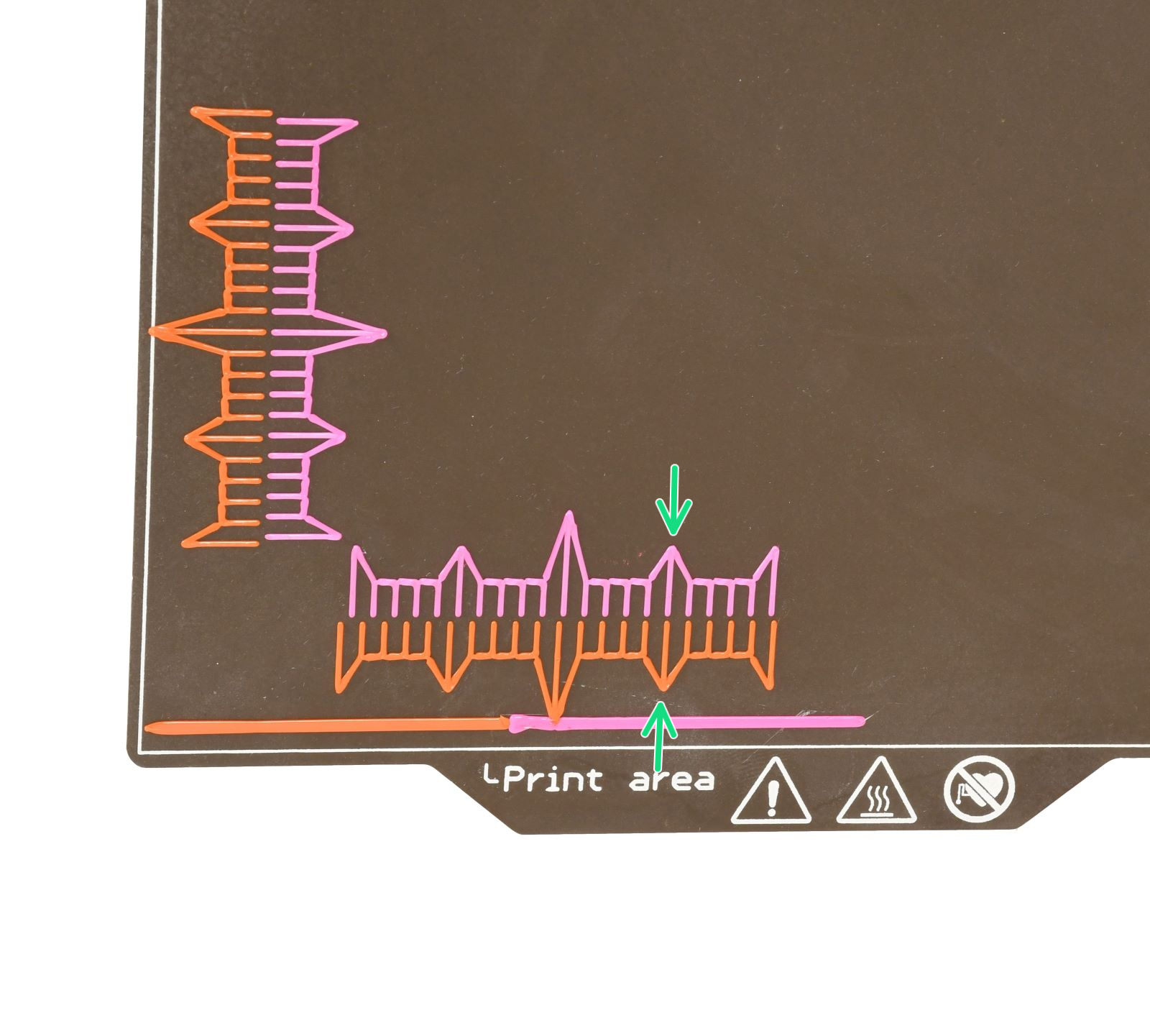

The print has two zones labeled X and Y, each with one comb for each tool, excluding Tool 1. For each comb, find the two marks in each zone that are most aligned with the comb printed with Tool 1 and read their values.

The largest mark represents 0 and the medium marks represent 0.5mm.

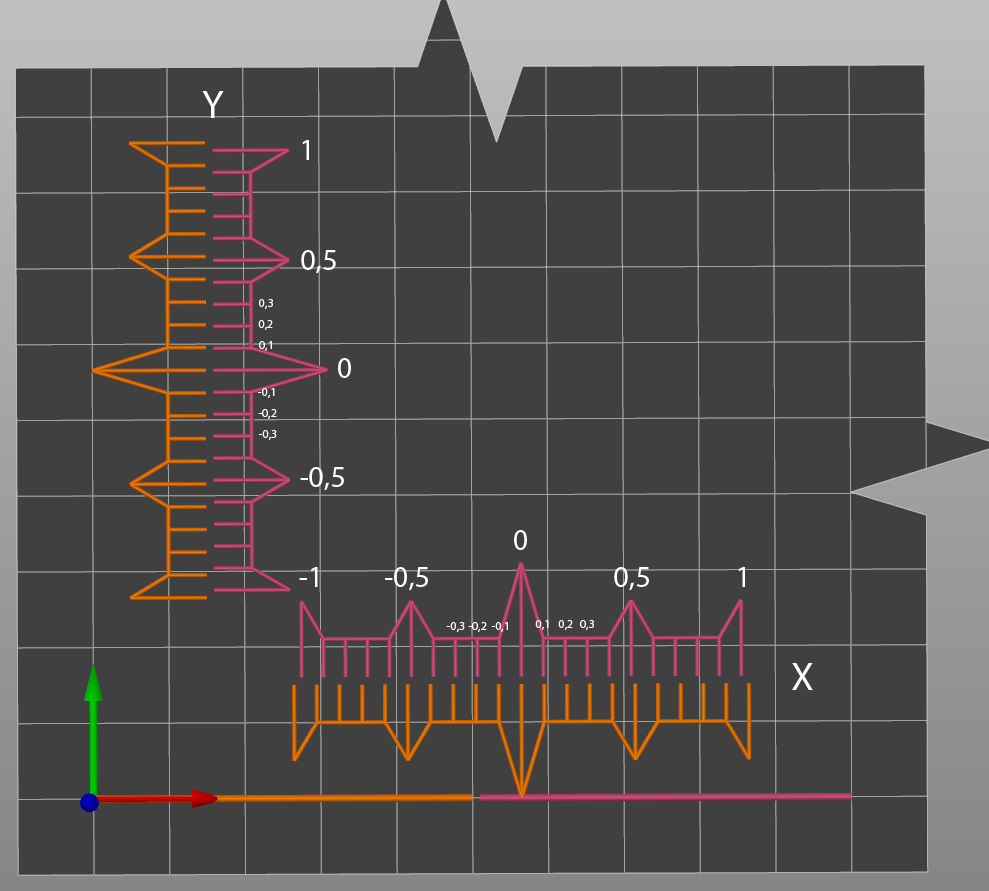

In the following visualization of the 2-Tool calibration GCode, the orange parts are printed with Tool 1, and the magenta parts with Tool 2.

|  |

In the right-side example picture, the most aligned marks correspond to a +0.5mm X offset.

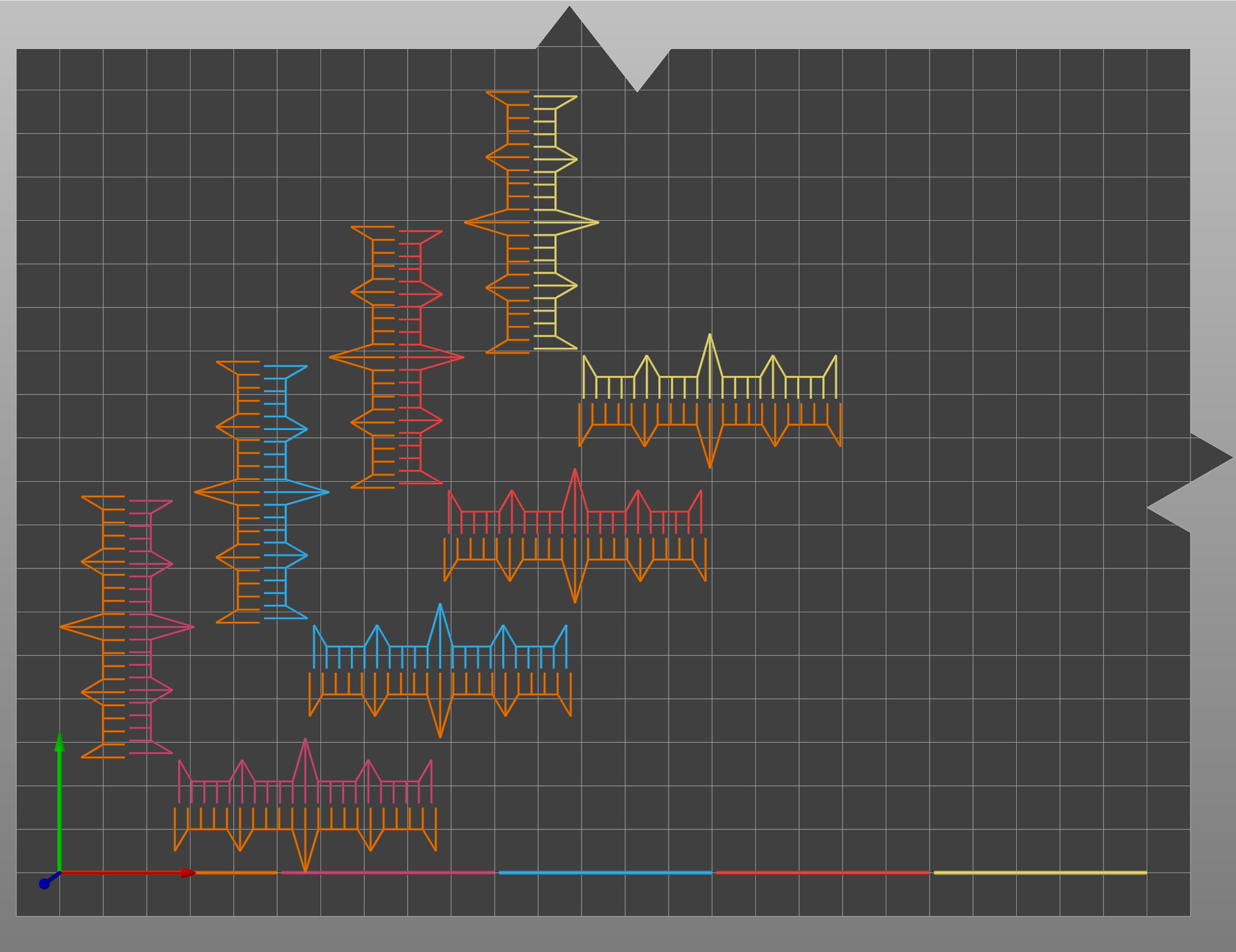

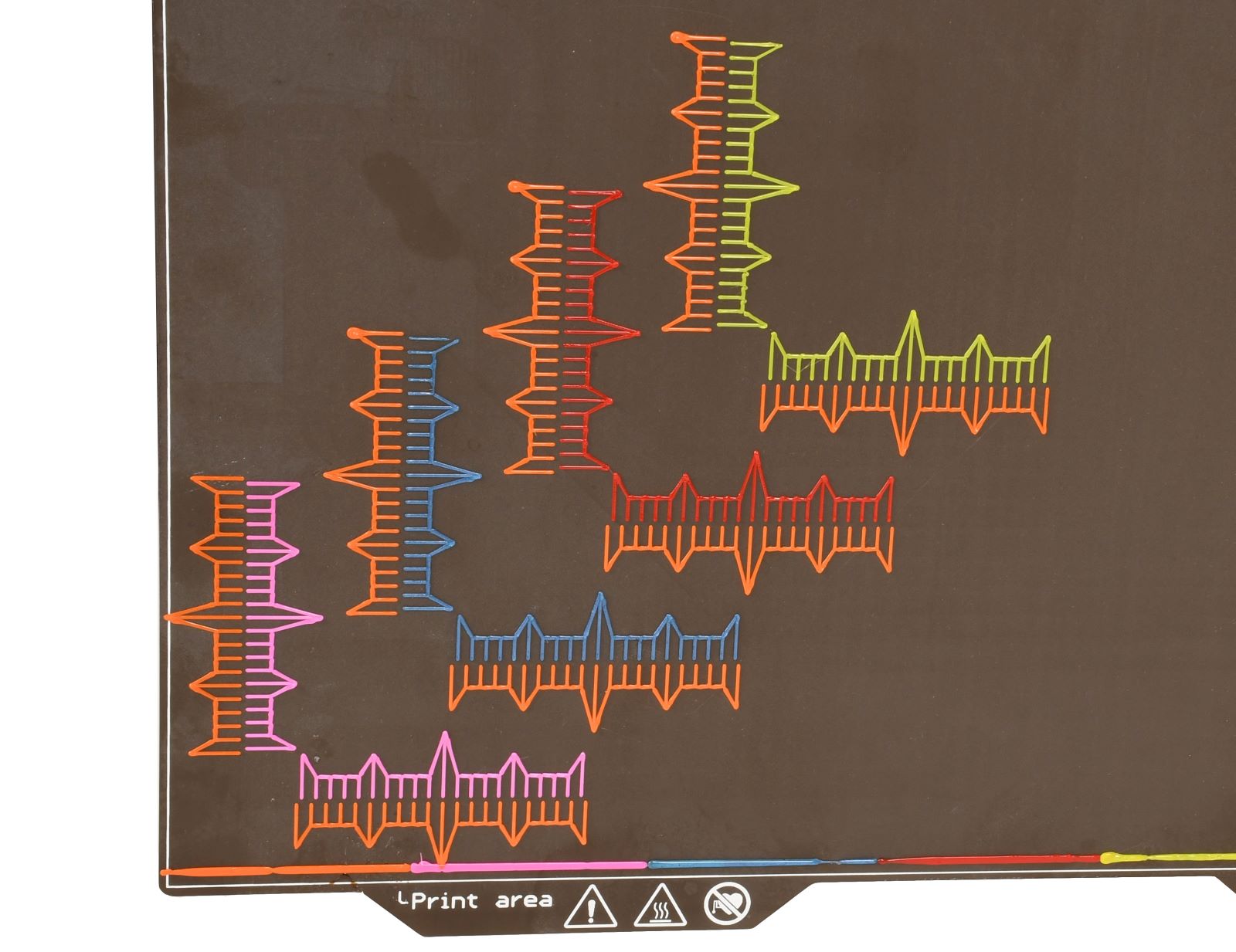

The 5-Tool calibration GCode has the same properties, but it has four combs per axis. Each tool offset is compared to Tool 1.

|  |

Procedure

- Print the model. Use one of the GCodes, to print in PLA, depending on the number of tools.

- After the print is finished, remove the steel sheet with the print still on, and observe the marks on each pair of combs.

- Find the most aligned marks for each pair, and read their value. If you are in doubt between two marks, choose their average value (for example, if 0mm and +0,1mm are both almost aligned, then choose an offset of +0,05mm).

- Adjust the offsets by adding the measured offset to the offset already shown for the selected tool in LCD Menu -> Settings -> Tool -> Tool # (the number of the tool is shown in place of #). For example, adding 0.05mm to Offset X in the screenshot would result in a final value of 0.071347mm.

For Tool 1 the offset value is not shown, as it is always set to zero.

- After correcting the offsets, remove any small plastic residues from the linear rails and belts to avoid affecting the homing position. Remove the print from the steel sheet, and print the test piece once again to check the alignment.

8 comments

Hello. First of all, check all your pulleys to ensure there isn't any debris or anything that could affect traveling distances. Then, try the tool offset calibration (available only for multitool). If that doesn't help, please contact our support team for assistance.