Your Original Prusa MK3S+/MK3S/MK3 printer may be causing some vibrations during use. In most cases, this will not cause any printing issues, however, we will show you how to minimize it or get rid of it entirely.

Identify the noise

Go to the Printer display -> Settings -> Move Axis, and Move X and Move Y individually to see if the noise can be narrowed down to a single axis. During operation/noise, try placing your hand on various components and hear if it dampens the sound.

Components such as:

- Heatbed

- PSU

- Motors

- LCD

Some sounds can be hard to identify and some may only present themselves with certain simultaneous movements. Therefore, we recommend inspecting all points outlined in this article, even if you are not sure exactly where the noise is coming from.

Inspect your printer

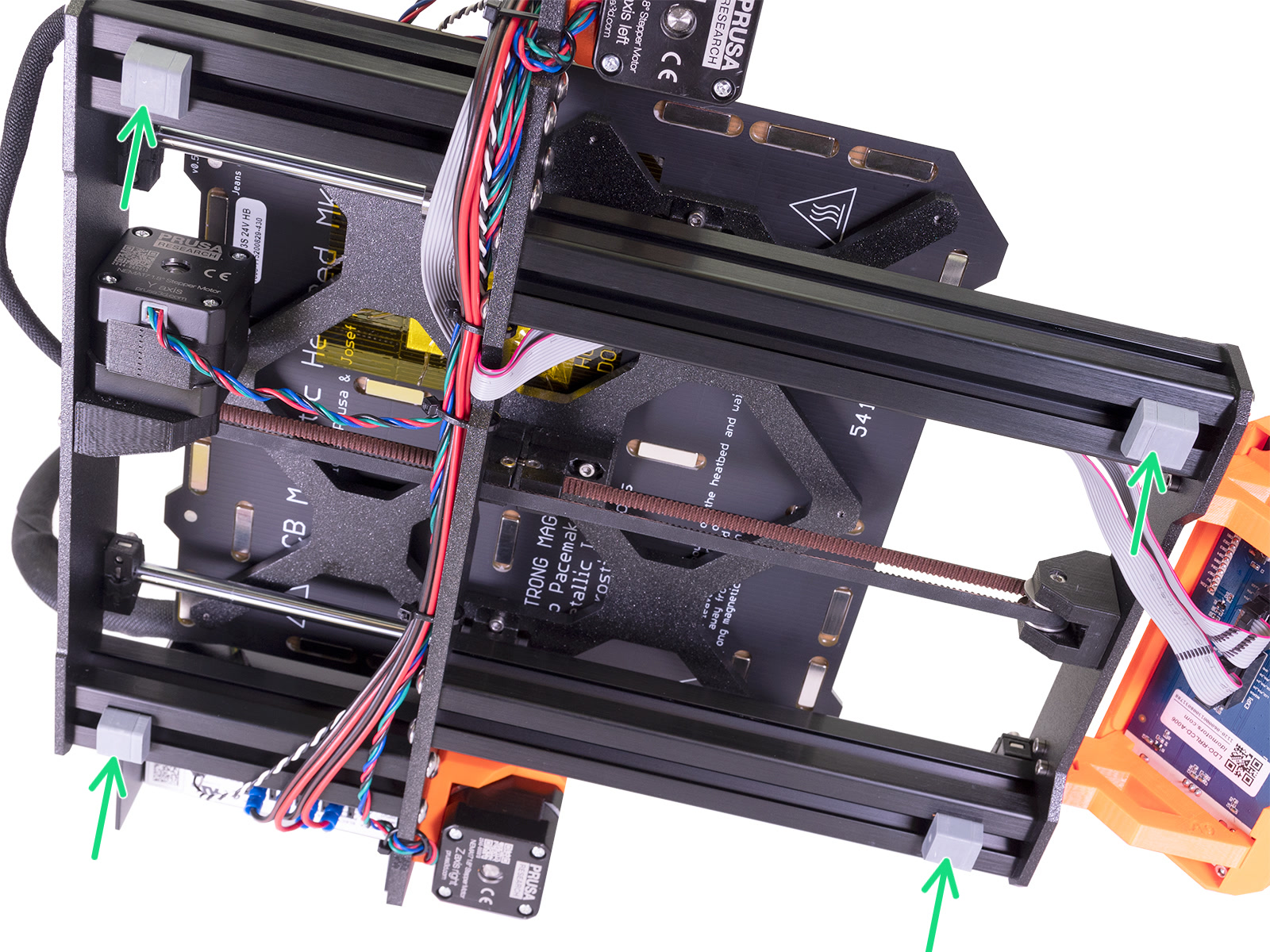

Rubber feet

The printer comes with 4 rubber feet (green arrows) that should be placed in the correct position, 2-3 cm from the end of each extrusion.

Lubricating rods and bearings

New noises coming from the printer after many hours of use is likely a sign that the rods and bearings could use some attention. For more information on how and with what to lubricate check out our maintenance guide.

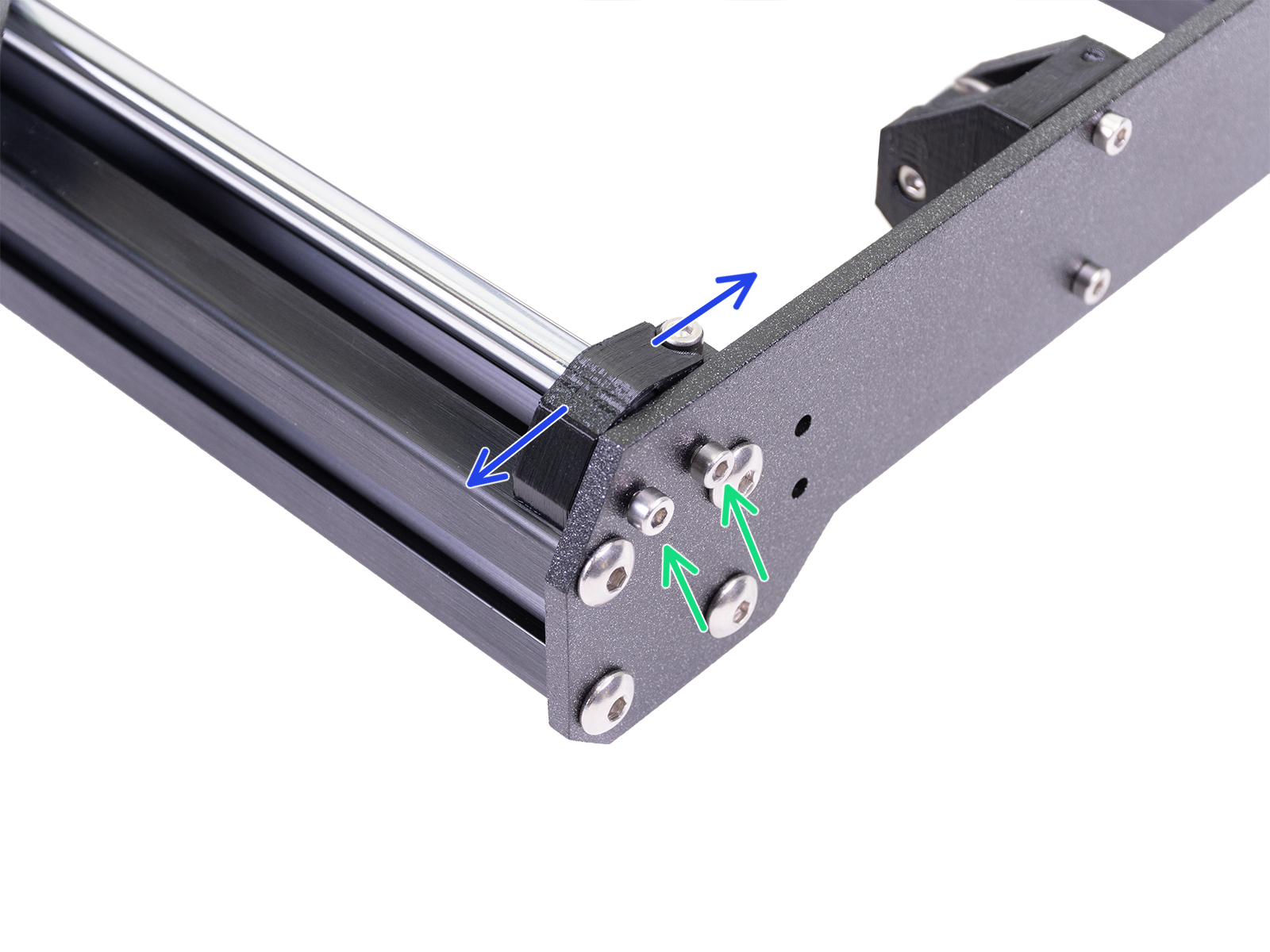

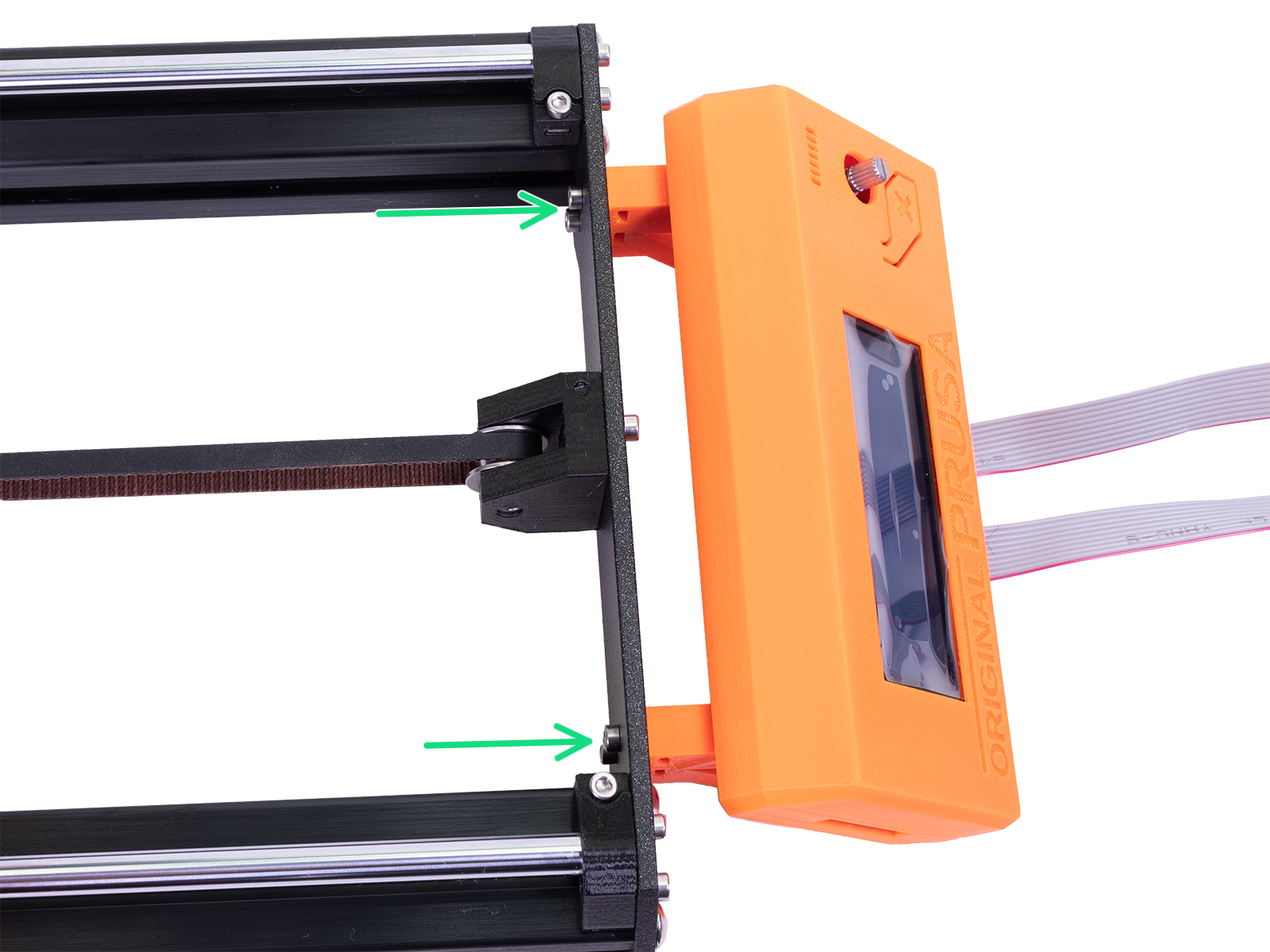

Align Y-rods

The Y-axis smooth rod alignment is part of the assembly manual and can greatly improve cases of sound and vibration.

The procedure is as follows:

- Losen all M3x10 screws on the four Y-holders half a turn (green arrows), so the printed parts are able to move (blue arrows).

- By hand, move the heatbed back and forth across the entire length of the axis to align them.

- Move the heatbed to the front plate and tighten all four screws of the front Y-rod-holders.

- Move the heatbed to the rear plate and tighten all four screws of the rear Y-rod-holders.

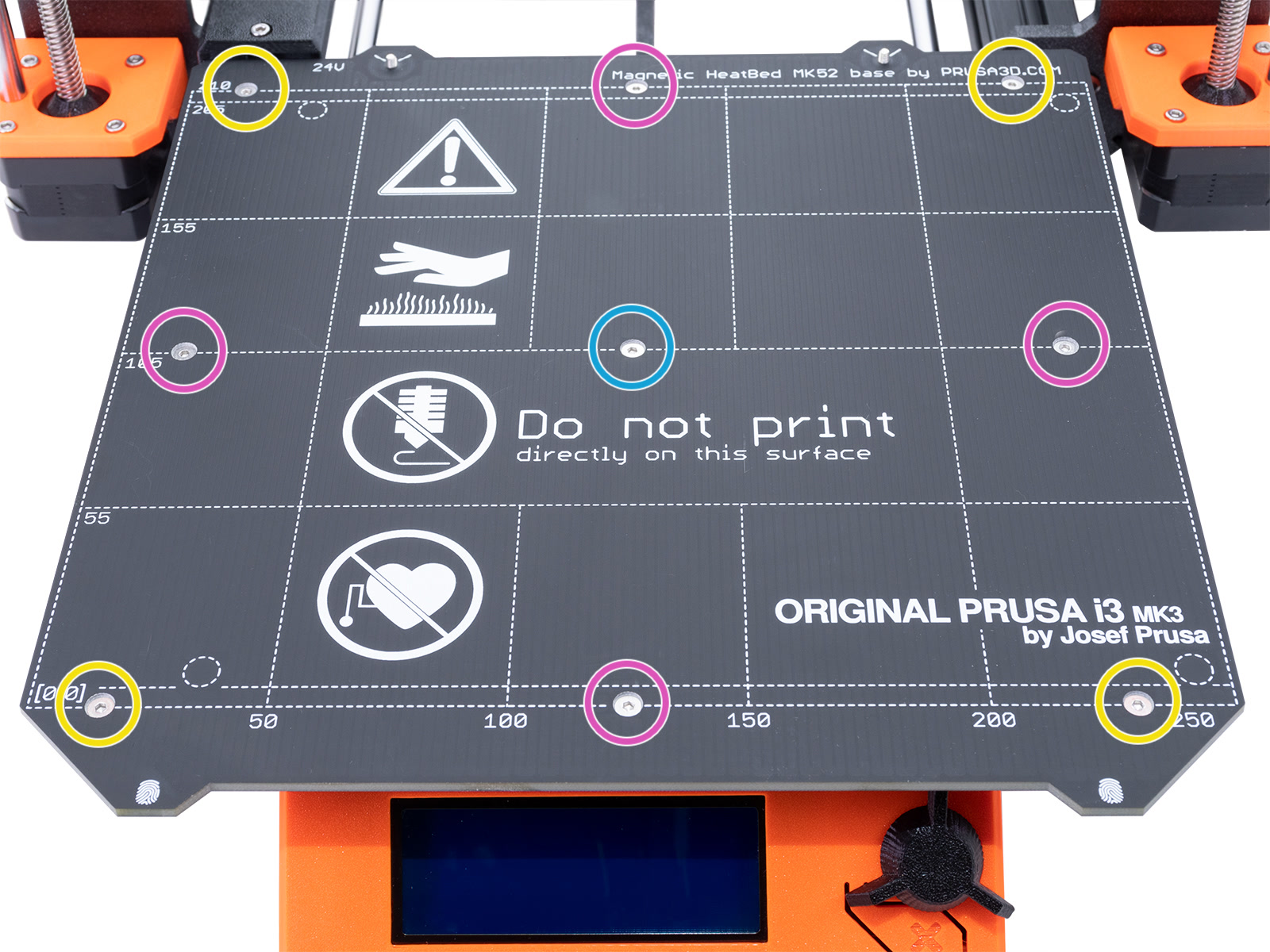

Heatbed screws

Check the 9 screws on the heatbed if any might be loose. If these are not well secured, the heatbed, screws, and spacers can rattle during movements. When tightening, always follow the correct order of:

- The center screw (light blue circles)

- The four edges (purple circles)

- The remaining four corners (yellow circles)

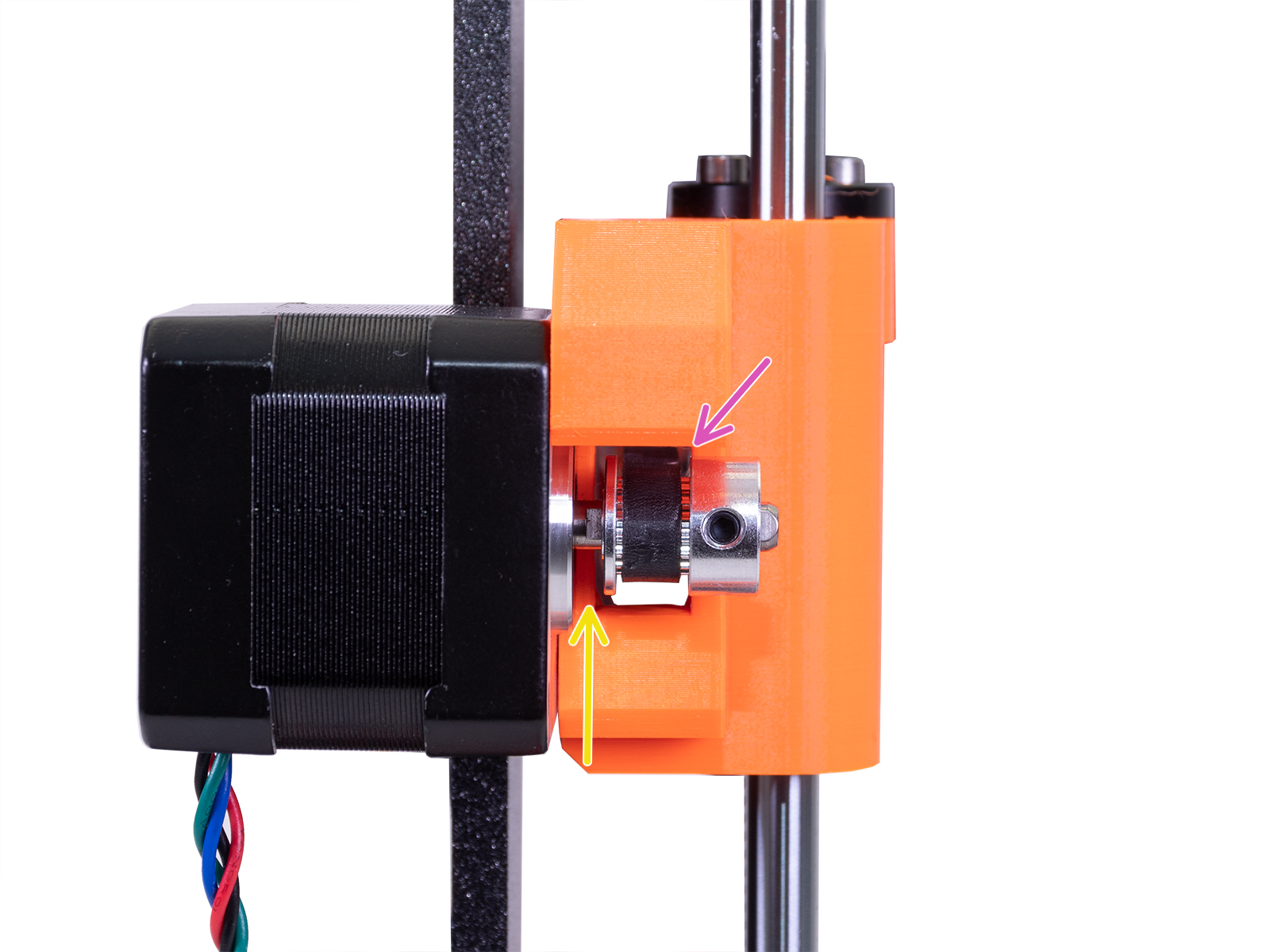

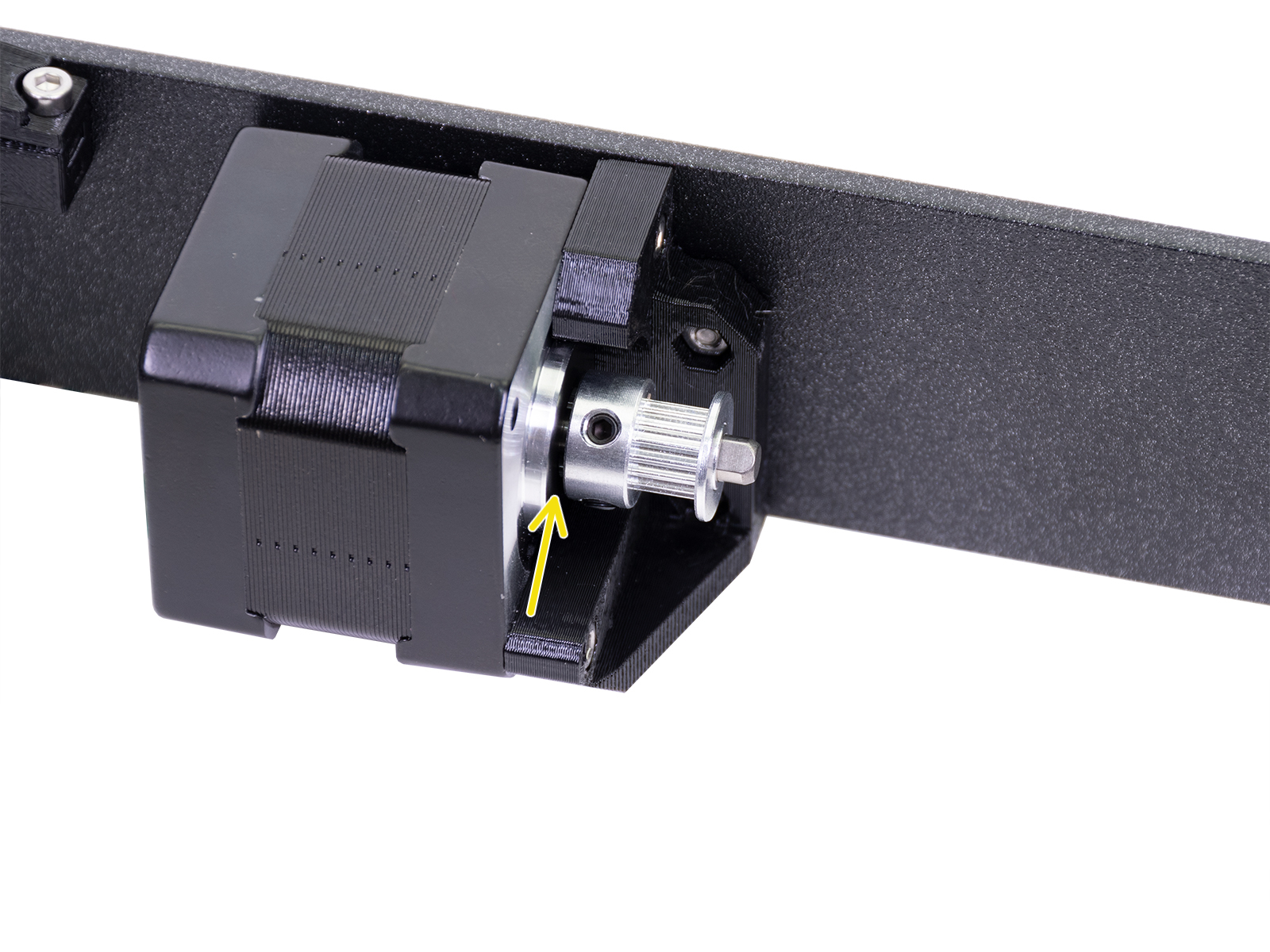

X and Y-axis pulleys

If the pulleys on the X and Y-axis are pushed against the motors, even just slightly, it adds resistance which leads to vibrations and even printing issues. Ensure that the spacing is correct (yellow arrow) and the pulley is oriented correctly.

Also, make sure the belt of the X-axis is aligned and not rubbing against a plastic part (purple arrow).

|  |

| X-axis motor with pulley installed. | Y-axis motor with pulley installed. |

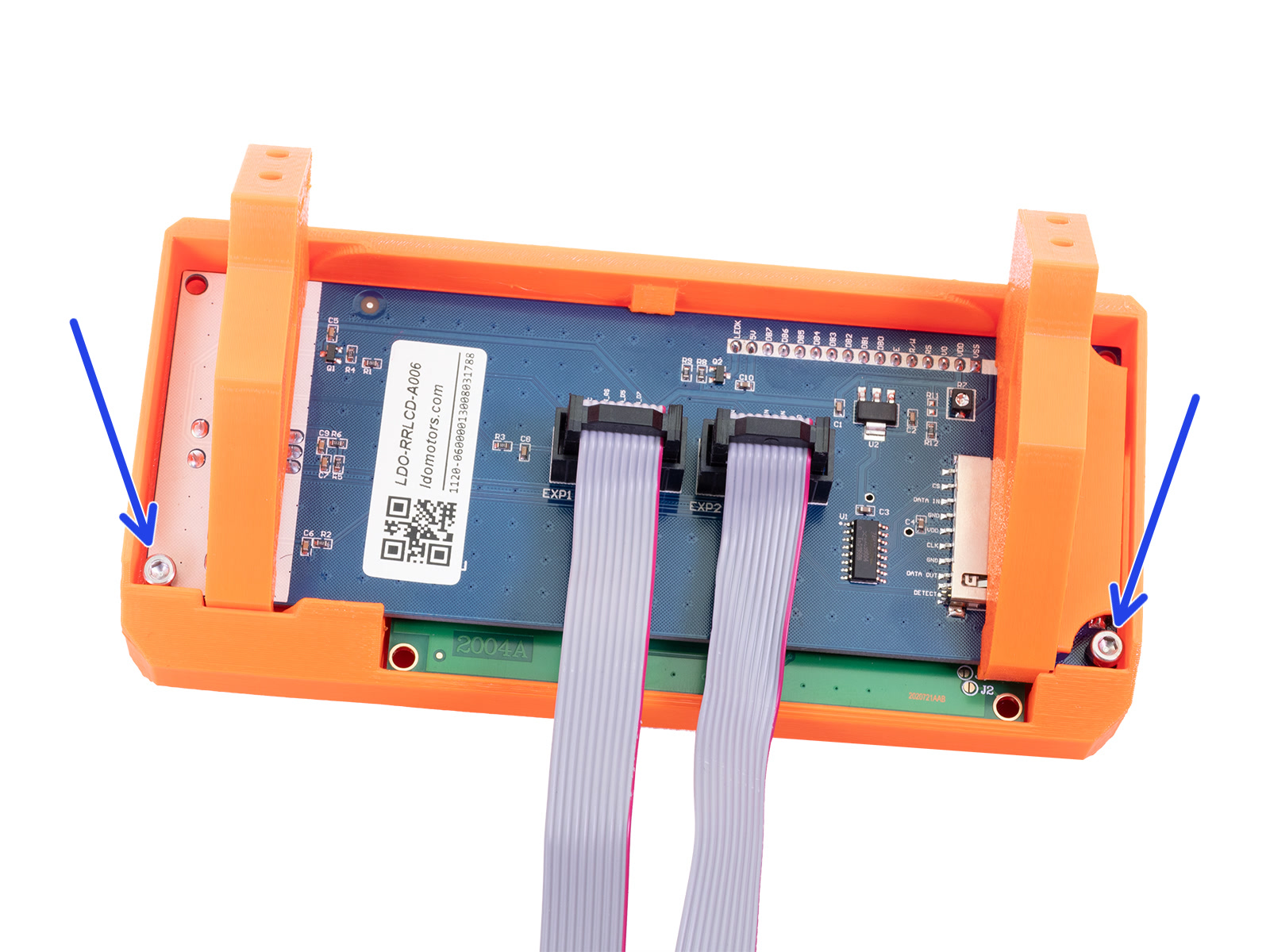

LCD-display

Loose screws securing the LCD module and the LCD assembly, can lead to vibrations as the Y-axis is moving. Make sure the screws securing the LCD assembly are tight (green arrow). The LCD module can also rattle during operation if not tightened all the way (blue arrows).

|  |

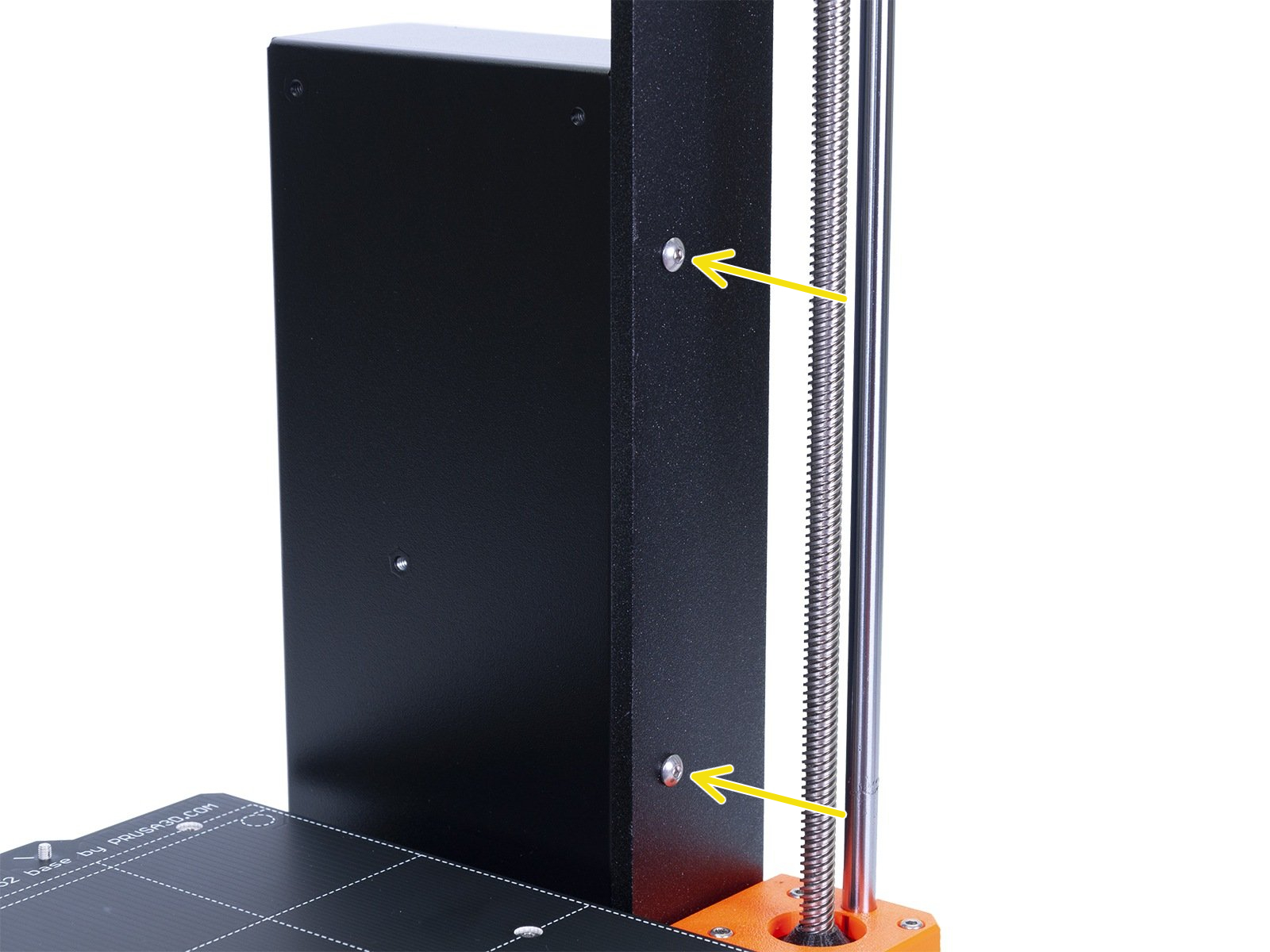

PSU

The PSU is secured with 4 screws: Two M4 screws on the side through the frame (yellow arrows) and two M3 screws at the bottom into T-nuts in the alu. extrusion (green arrows). Make sure all 4 of these are secure.

|  |

Other tips and tricks

Surface the printer stands on

The surface that the printer is on can amplify any of the vibrations and noises coming from the printer. The surface the printer is on should be steady and firm, and should not wobble during printing or if pushed by hand. A hardwood table is an example of this.

This can be enhanced further by placing the printer on a concrete slab/tile which would eliminate any vibrations traveling into the table/desk the printer is standing on.

Padding under the printer

An easy solution to dampening the noise and vibration of your printer is to add some sort of additional padding underneath the printer. This will dampen any sound resulting from the resonance between the

printer and the surface the printer is resting on.

You can use something you have around the house. Such as a folded towel or foam padding like you may find in children's play areas.

7 comments

Hi! Three bearings for the heatbed is the most forgiving setup in case the printer is built skewed or has other hardware issues. Check if your Y motor doesn't rattle between the motor chassis and the Y-rear plate.

quote: "MISUMI Linear Bushings are applied with Anti-rust Oil harmless to the bearing lubrication greases. After de-greasing the Antirust Oil, application of grease is recommended."

Prusa should add lubing the bearings with grease to the manual. It will be a lot less hassle disassembling the 3 axis again for lubrication once you figure this out.