What happened?

When the MMU unit unloads a filament from the extruder, the filament sensor inside the extruder should stop detecting the filament. In case it does not, this error appears.

How to fix it?

Check the PTFE tube that leads from the MMU unit to the extruder, and see if the filament has been unloaded or not.

In case the filament has been unloaded, but the printer shows this error, remake the filament sensor calibration.

Extruder

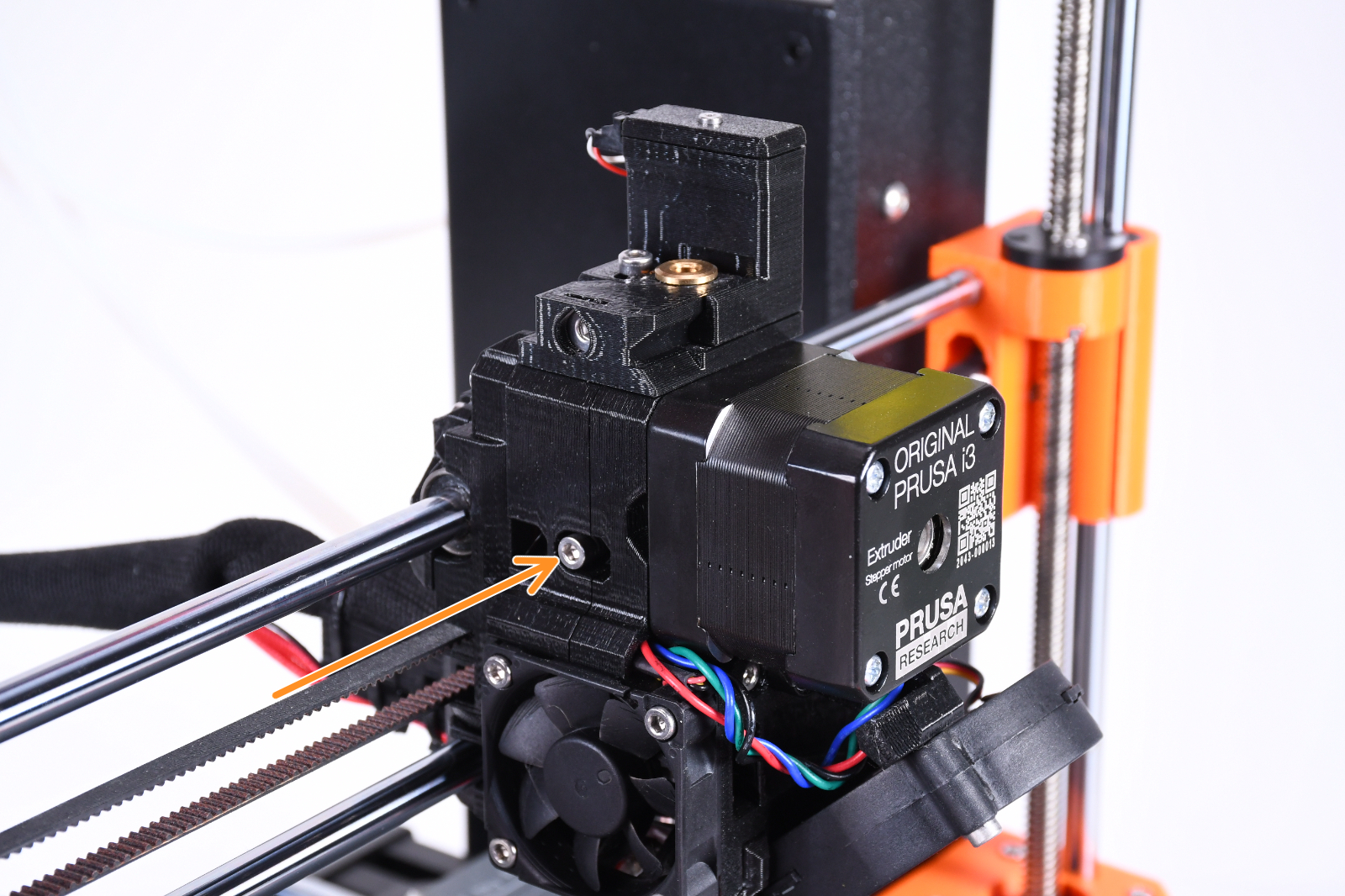

In case the filament has not been unloaded, make sure that the nozzle is heated for the filament you are using. Then open the Extruder idler screw and the Festo fitting on the top of the extruder, and manually pull the filament. Note that some force might be necessary.

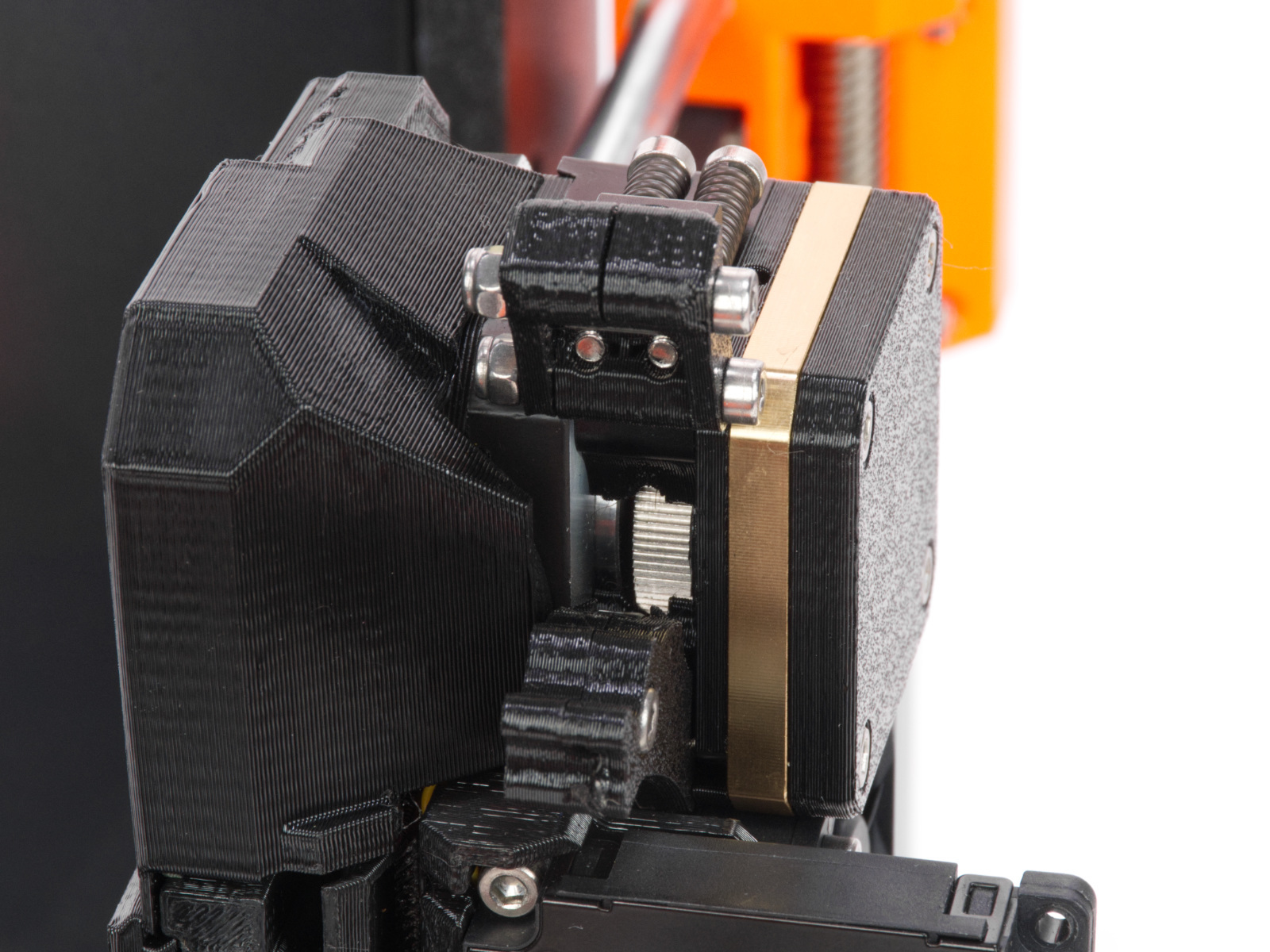

On the MK3S, check the alignment of the idler door and the Bondtech gears. On the idler door, check if the gear is moving freely and that the shaft is connected to both sides of the plastic part.

Make sure that there is no debris or pieces of filament in the idler door or extruder gears causing the filament sensor to falsely trigger.

|  |

| MK3S/+ | MK4 |

Filament

Check that you are using the correct settings for your filament with the manufacturer. Filaments that have a lot of stringing might cause the filament to jam.

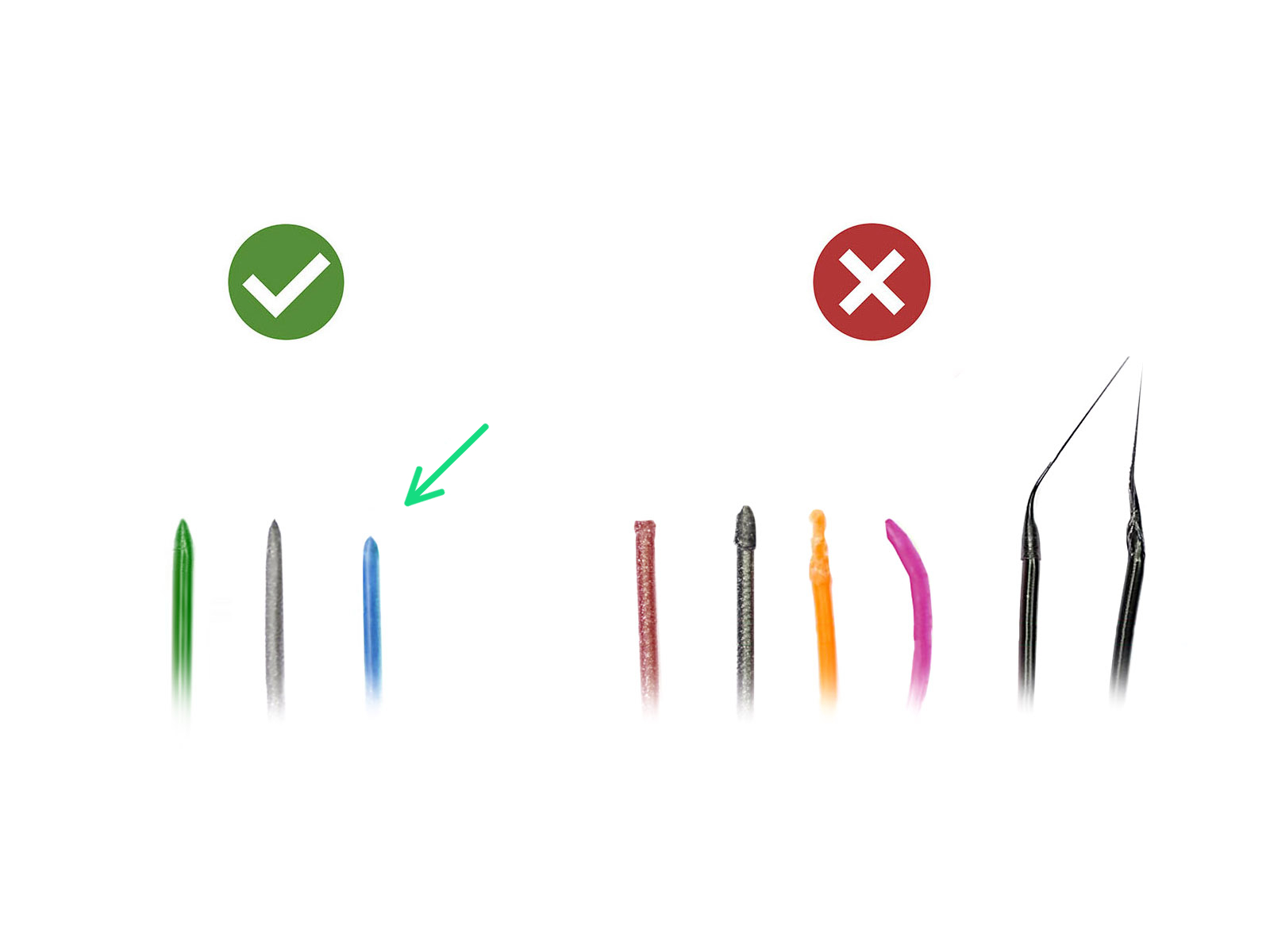

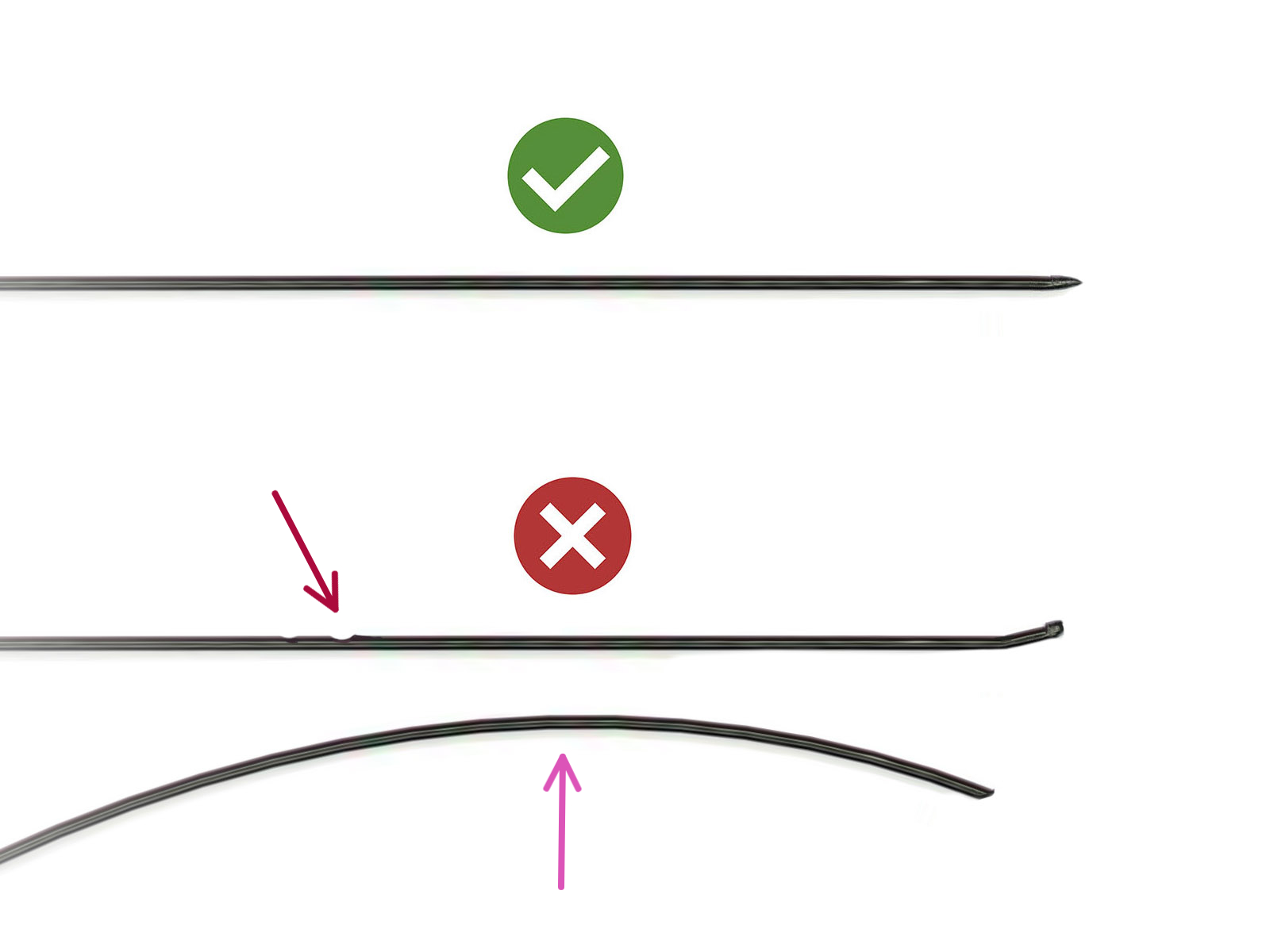

Before starting the printer operation again, make sure that the filament is straight and cut into a sharp tip, and that there is no damage on the first 40 cm of the filament.

In case the issue continues to happen over multiple unloads, check the extruder for clogging.

In case the issue persists due to deformed filament tips, try changing the PTFE tube.

|  |