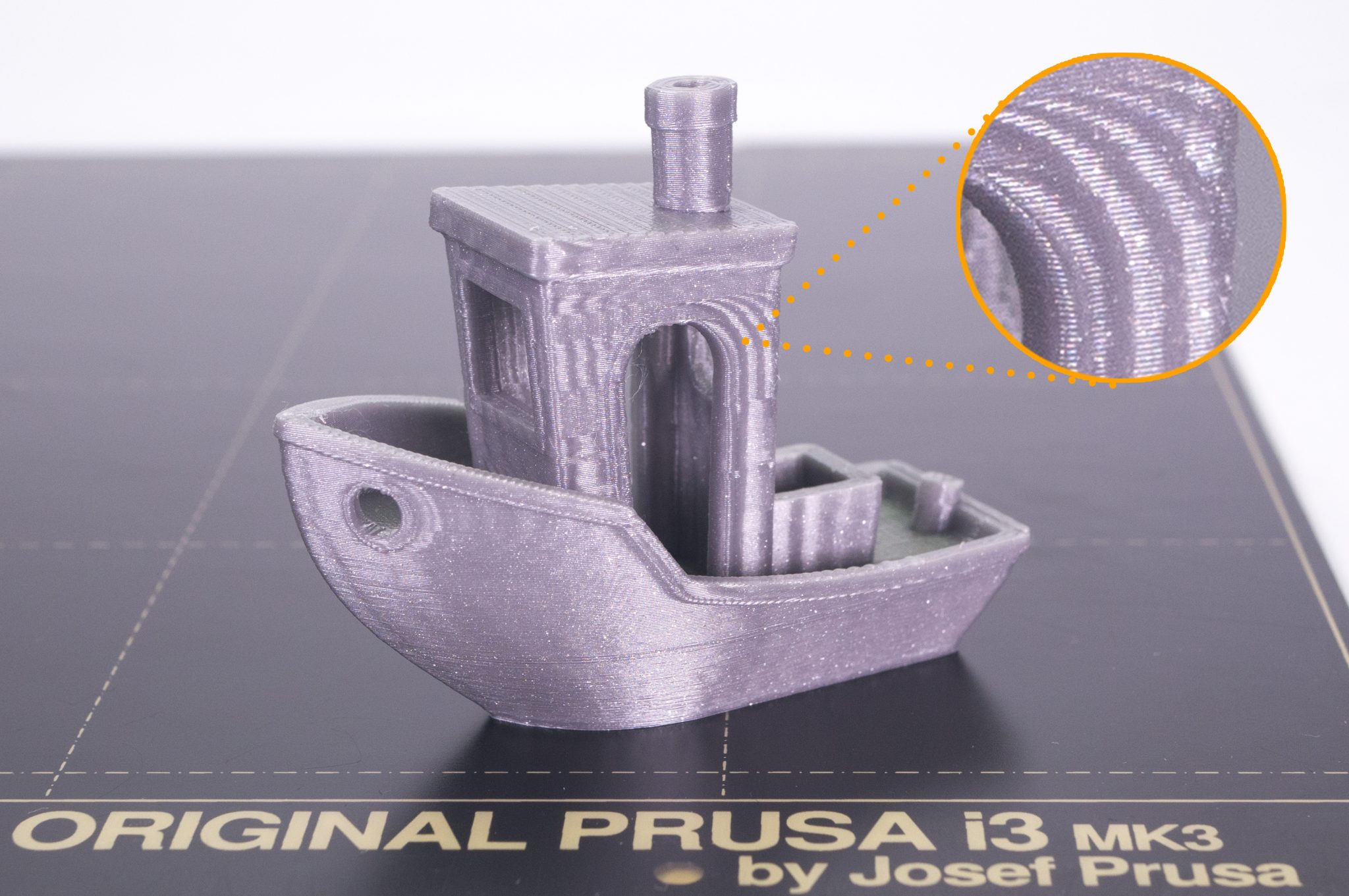

Ghosting can be typically recognized by several waves that follow after a sharp edge of a model. An example can be seen in the photograph of 3DBenchy at the marked spot.

How to fix ghosting (MK2/2.5/S and MK3/S):

Adjust belt tension on X and/or Y axes. It may take a bit of time to find the perfect belt tension. We can offer the following tip: try plucking the belt like a guitar string. You should hear a deep bass tone. A belt that has been tightened more will emit a higher tone. A less tightened belt will result in a lower tone.

You can also check the Belt Status values which can be found in the printer’s LCD menu. Go to Support -> Belt Status and check the measured values. Values between 240 and 300 are fine. These values are updated each time you run the Selftest (LCD menu -> Calibration -> Selftest), or that you run a belt test (LCD menu -> Calibration -> Belt test). A lower value means more belt tension, a higher value means a more loose belt. For more information about how to change the belt tension, check the guide Adjusting belt tension (MK4/S, MK3.9/S, MK3.5/S, MK3/S/+).

How to fix ghosting (MINI):

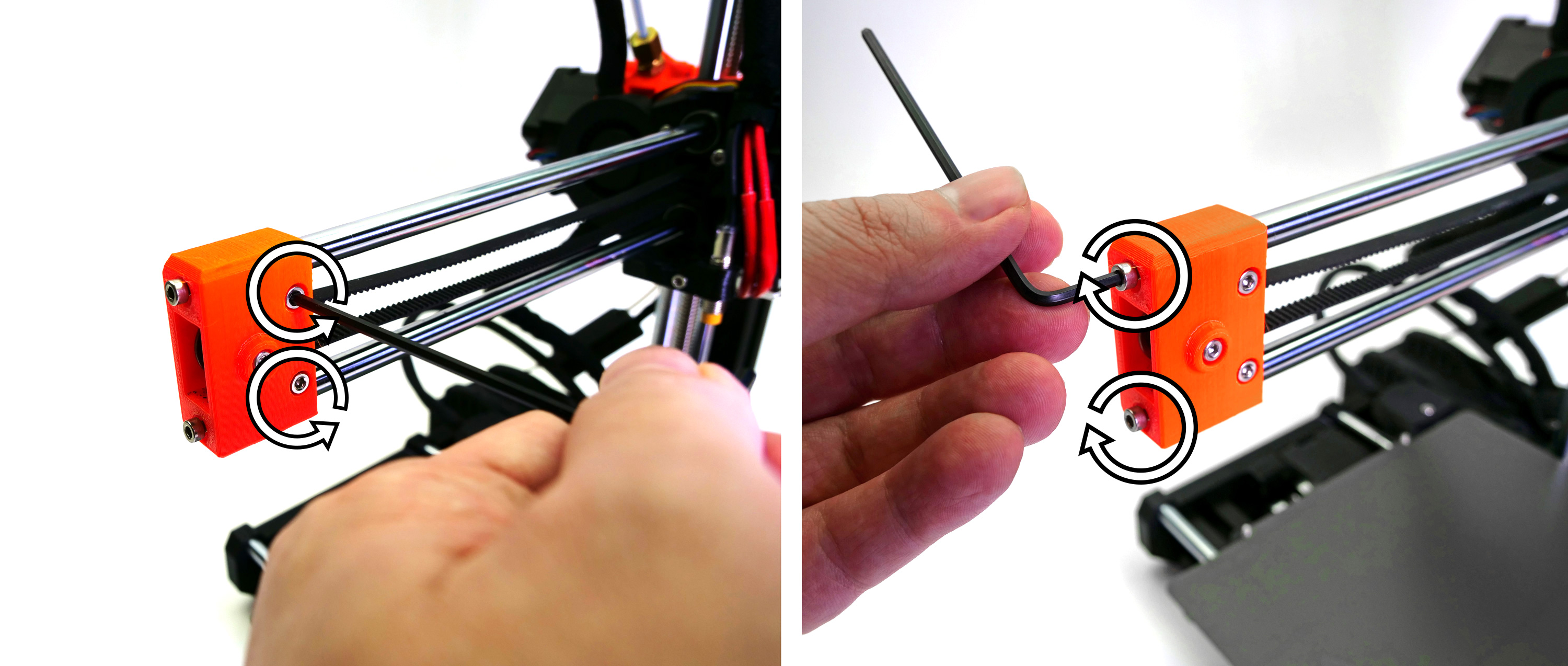

Check the X/Y belts. Make sure that belts are properly tightened. Belts should be tight enough to sound like a low bass note when plucked. If the belts are loose, tighten them first: first, loosen the two screws as depicted below. Then, tighten the two screws at the very end of the X-axis. They go directly against the metal rods, so the more tightened they are, the further you move the plastic part. Once you are done, tighten the first two screws again to fix the part in place. For more information about how to change the belt tension, check the guide Adjusting belt tension (MINI/MINI+).

General advice:

The problem of ghosting can be visible also when belts are properly tightened. Ghosting is caused by vibrations that increase with print speed. To reduce ghosting, try to reduce the printing speed and see if the problem goes away. It’s always better to place the printer on a firm surface.

2 comments