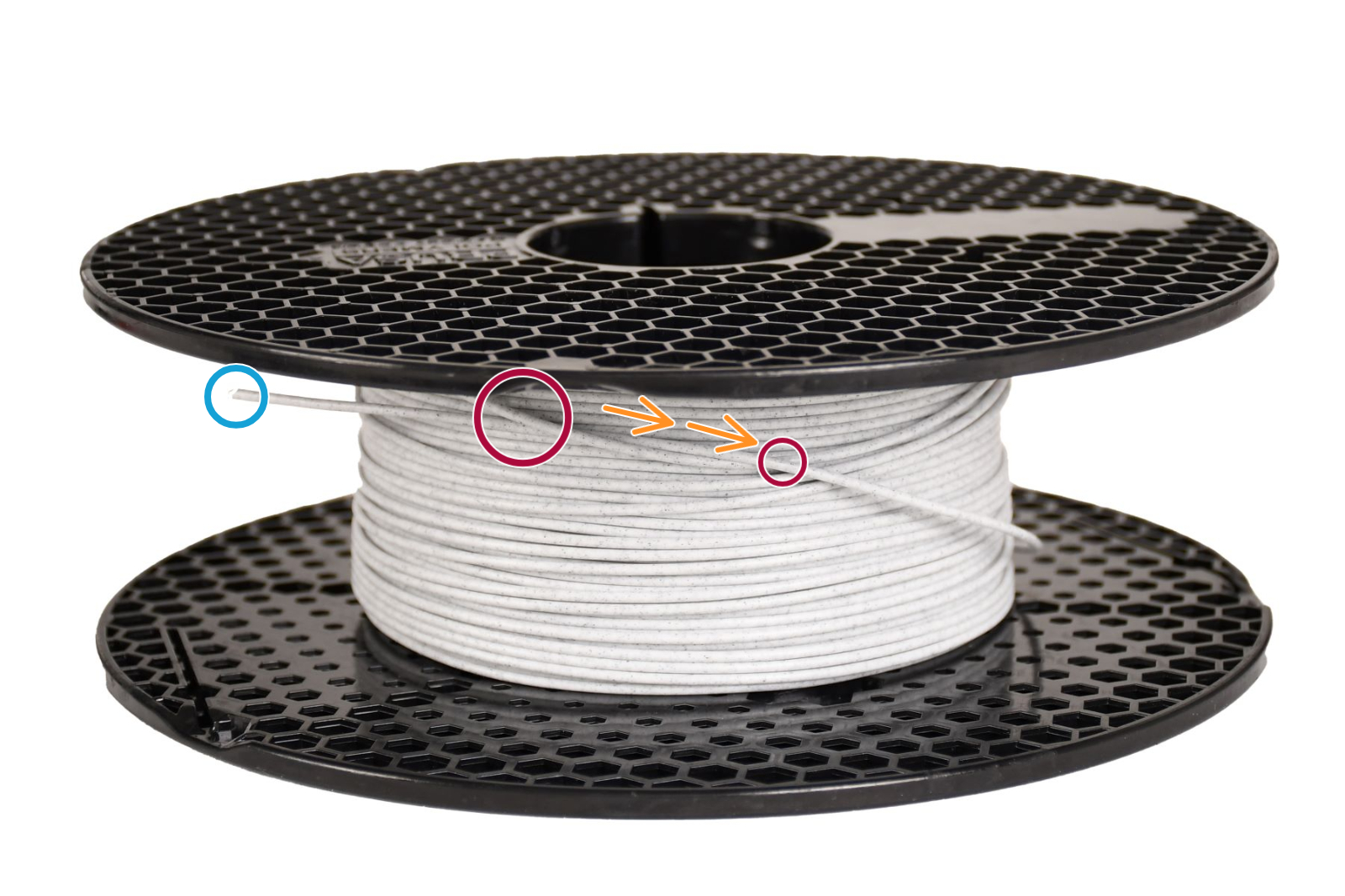

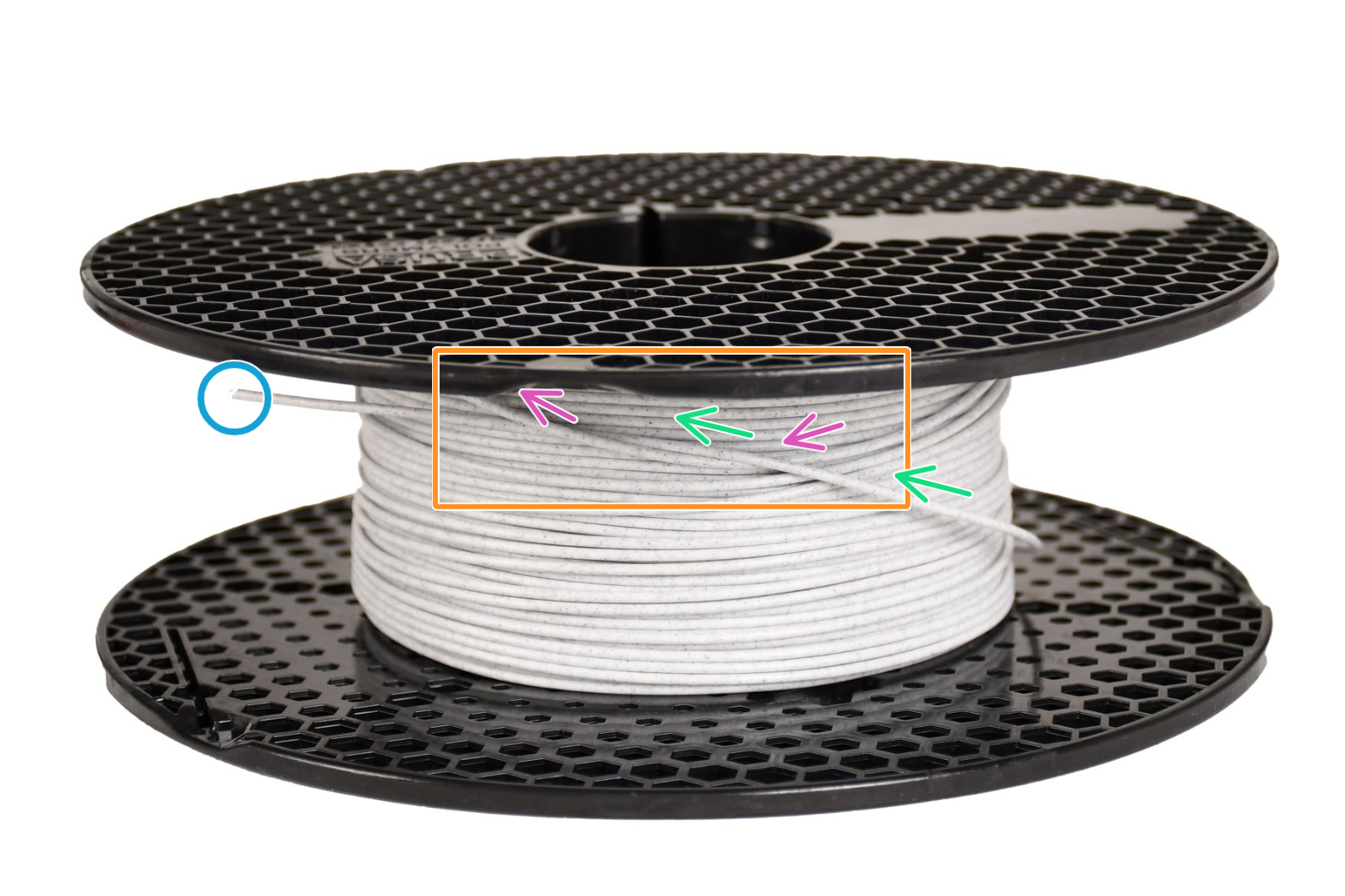

A tangled filament spool can cause a print to fail, as a knot can form on the filament strand. This is caused by letting the filament end go, for example during a filament unloading, causing the filament end to go under another loop. As a visual example, notice the path of the spool parts indicated with green and magenta arrows, inside of the orange rectangle.

Winding

The filament in a spool is a single, continuous string wound at once from start to finish. It is physically impossible that, during production, a filament coil can get under another.

Perfect winding refers to the filament sitting nice and tidy on the spool, with no overlaps. It is our way of making Prusament visually pleasing.

Even though a spool does not have perfect winding, this doesn't have an influence on it being prone to tangling.

How to prevent tangling

To prevent filament tangling, do not let go of the filament tip whenever the filament is not loaded. Once you are ready to store the spool, put the filament tip on the spaces on the spool, for example on any of the honeycombs for Prusament spools.

How to untangle

Identify the knotted strands, and gently untangle the knot from that point, without bending the filament. After that, rewind the loose strands by gently rotating both the spool and the coil. Never let go of the filament end, until this is secured on a hole on the side of the spool.