Basic info

Description

BVOH (Butenediol vinyl alcohol copolymer) and PVA (polyvinyl alcohol) are water-soluble materials ideal for printing supports for models with complicated shapes, where the non-soluble supports would be difficult to remove. The best combination of materials is using PLA with BVOH or PVA due to their similar printing temperatures. Both BVOH and PVA are very hygroscopic and should be kept as dry as possible. One gram of BVOH is soluble roughly in 20 g (ml) of water. BVOH and PVA are non-toxic materials printed with no odor.

The main difference between BVOH and PVA is in their printability and price. PVA is usually cheaper, but it’s more prone to nozzle clogging. Although both filaments show inferior print surface adhesion, BVOH sticks a little bit better than PVA.

To compare supported material properties, see our material table.

|

Pros |

Cons |

|---|---|

|

✔ Good for printing easily removable supports |

✖ The filament must be kept dry |

|

✔ Low printing temperature (the same as for PLA) |

✖ Necessity of larger volume of nozzle purging (cleaning) |

| ✔ BVOH & PVA are non-toxic materials |

✖ High price |

Best use

Water soluble filaments are great for printing easily removable supports.

Tips for successful printing

Print it with PLA

BVOH and PVA are ideally used together with PLA as the material of the main model because of their similar printing temperatures.

Keep it dry

We recommend making a drybox for filaments that require keeping them as dry as possible.

Adjust the distance between the supports and the model

The distance between the supports and the model in the Z-axis should be set to 0mm (water soluble). This way, you will achieve the best results with bottom layers looking almost as great as the top ones.

Try to print BVOH or PVA on PLA raft.

It’s optimal to choose models that don’t require printing BVOH/PVA directly on the print surface. Or creating a raft (1-2 layers) from PLA is also a good choice - BVOH/PVA sticks much better to PLA than to PEI print surface. More information on this in Water-soluble materials (PVA/BVOH).

Material solubility

Dissolving BVOH and PVA takes several hours, depending on the amount ratio of material and water and also on the water temperature (warmer is better, but it can not be too hot either). Frequent filament changes can lead to printing residual PLA into the soluble supports. This can prevent the BVOH/PVA from dissolving entirely. This effect can be moderated with an increase of purging (cleaning) material.

Sample prints

|  |

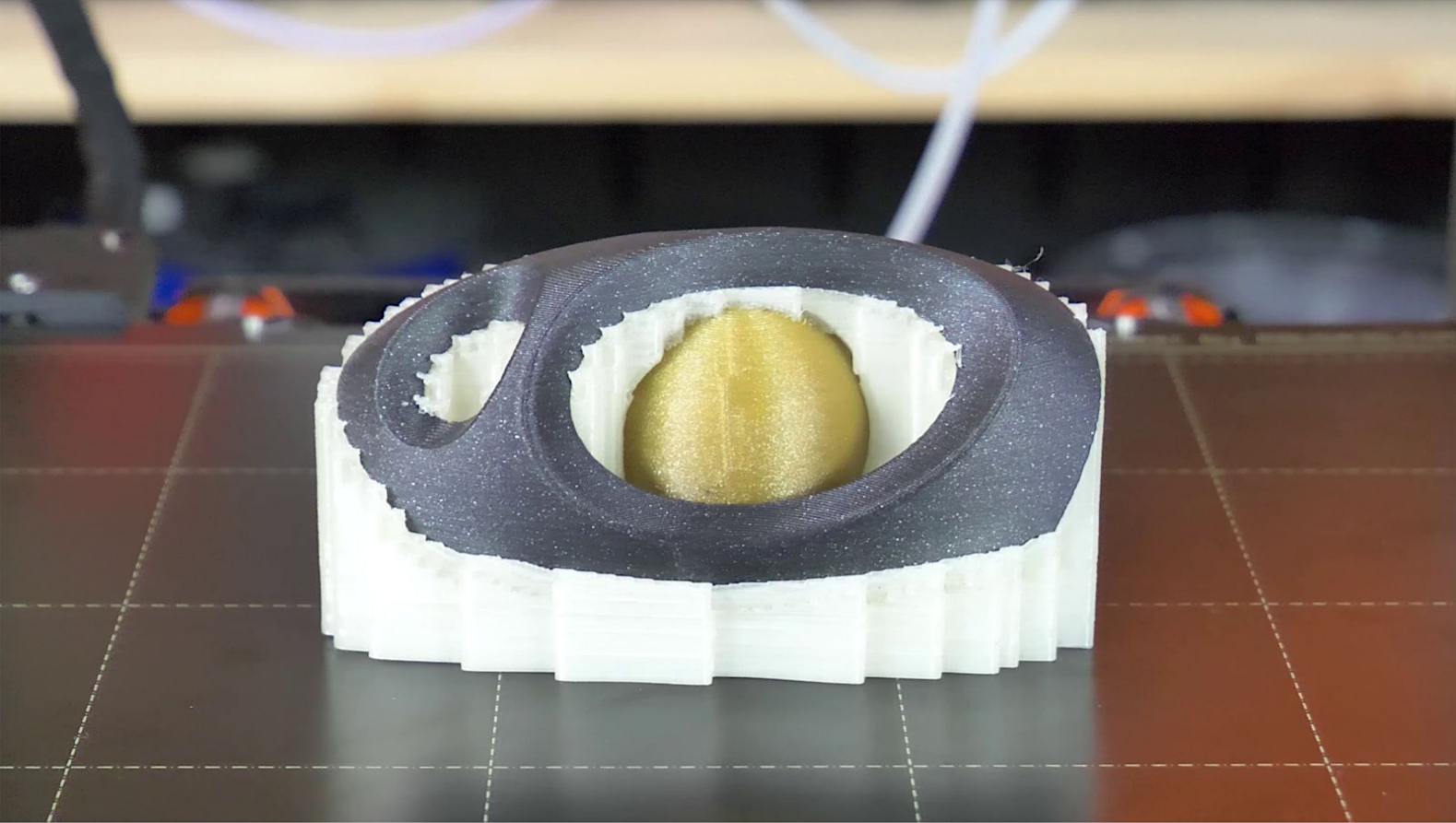

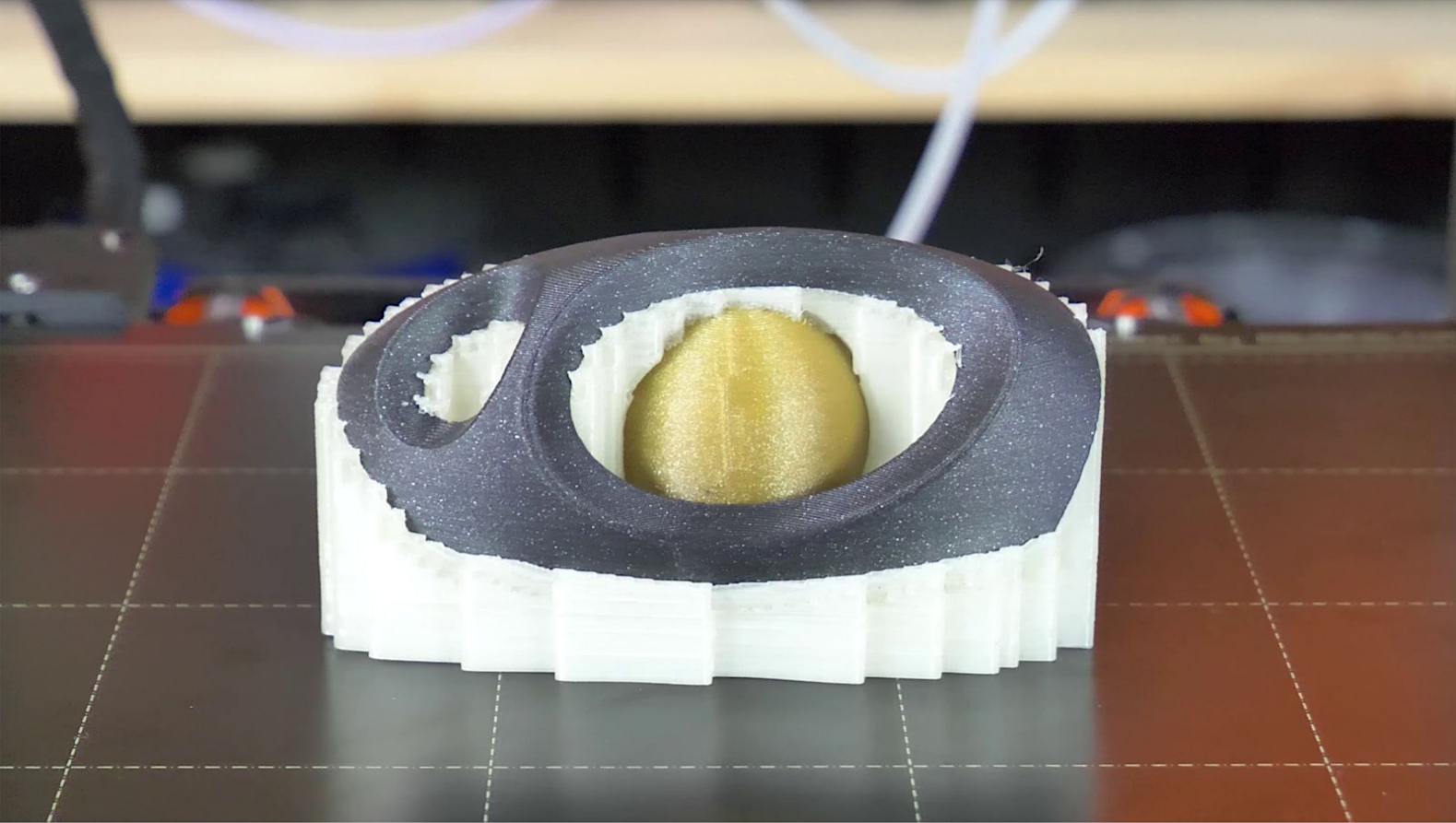

| MMU2S print with soluble supports | Printing with soluble materials might be challenging |

3 comments

https://www.prusa3d.com/category/support-material/