⬢Please prepare tools for this chapter:

⬢1.5mm六角レンチでナットの位置合わせが可能

⬢M3 ネジ 向けの 2.5mm 六角レンチ

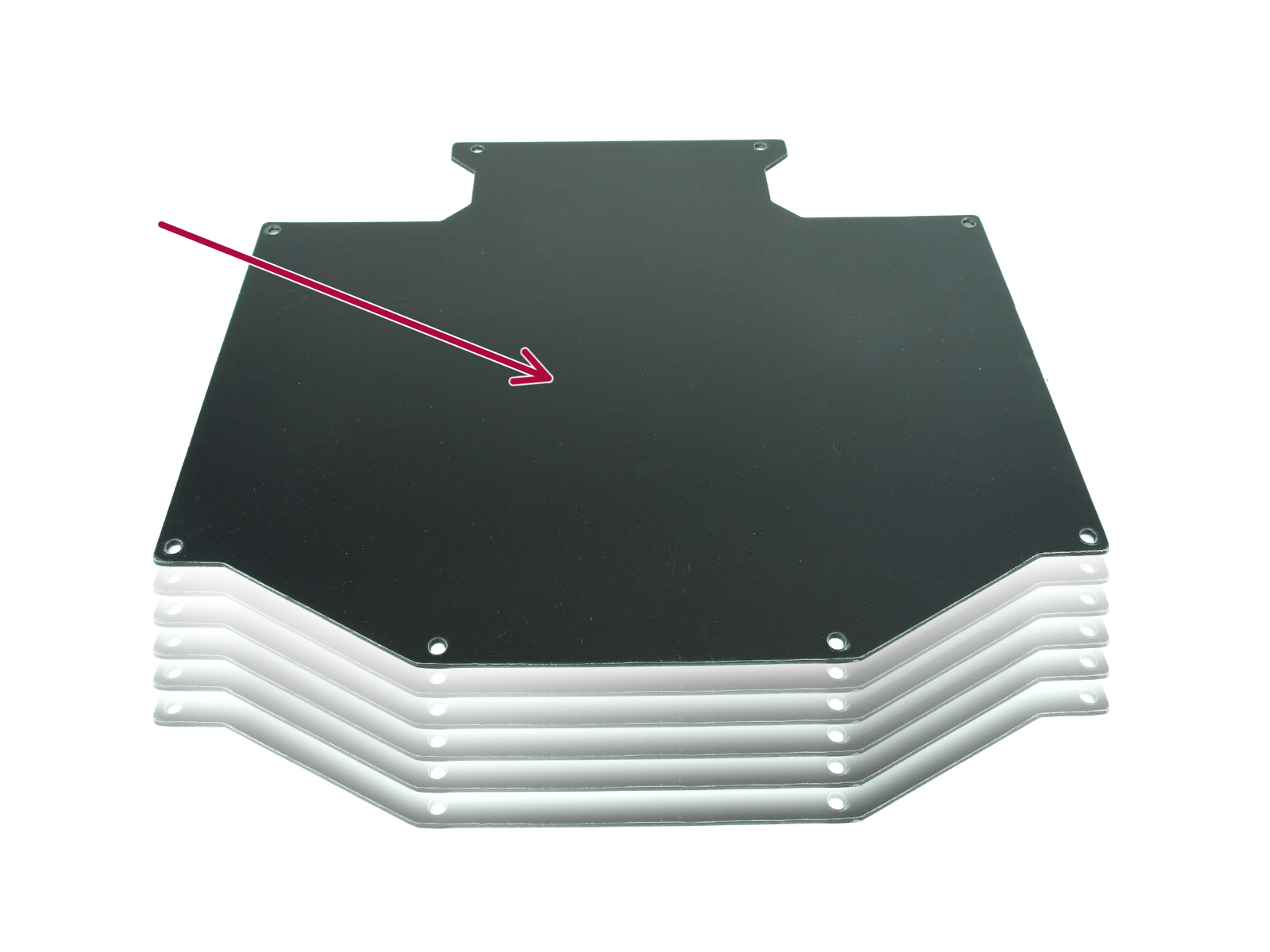

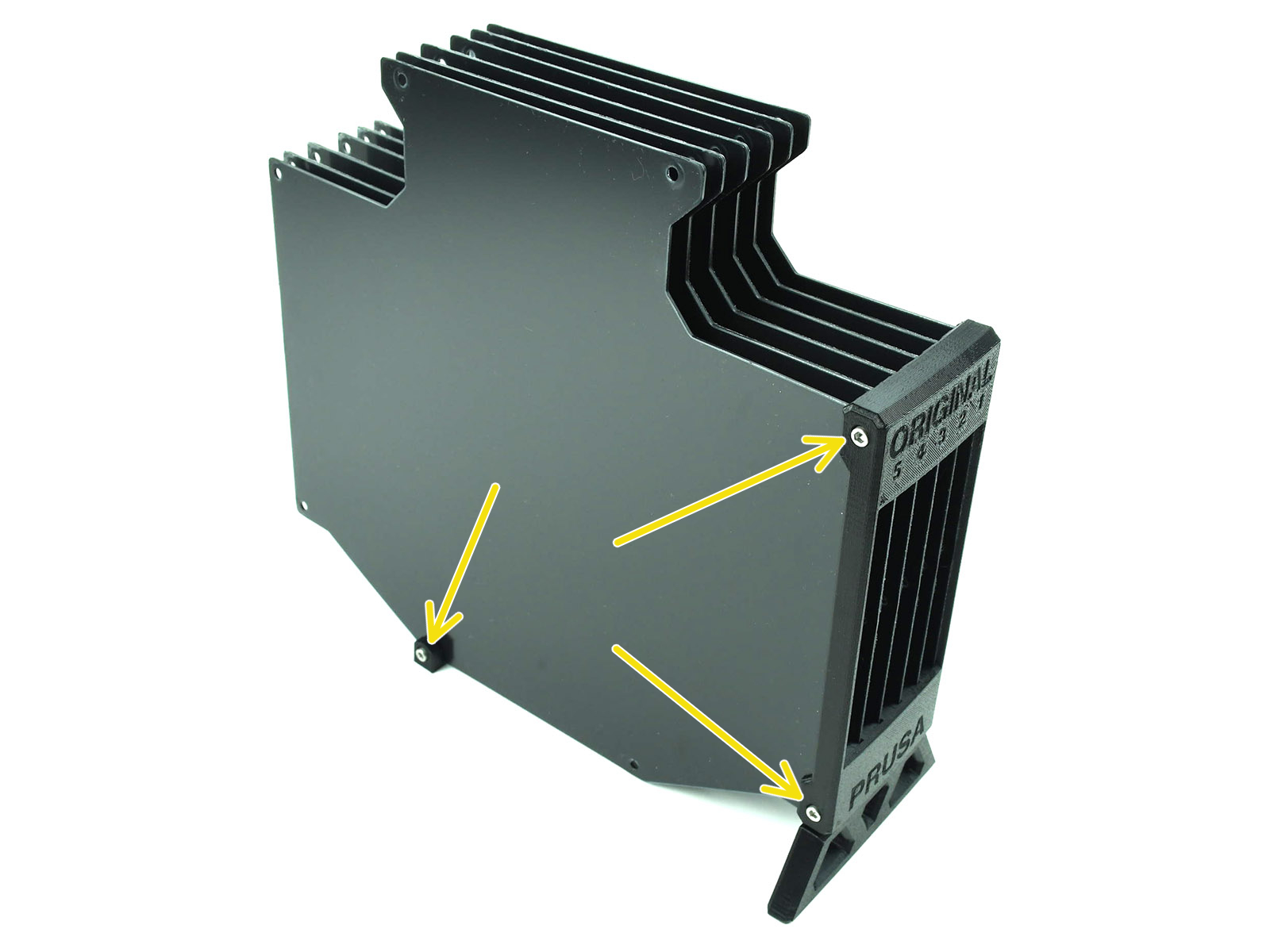

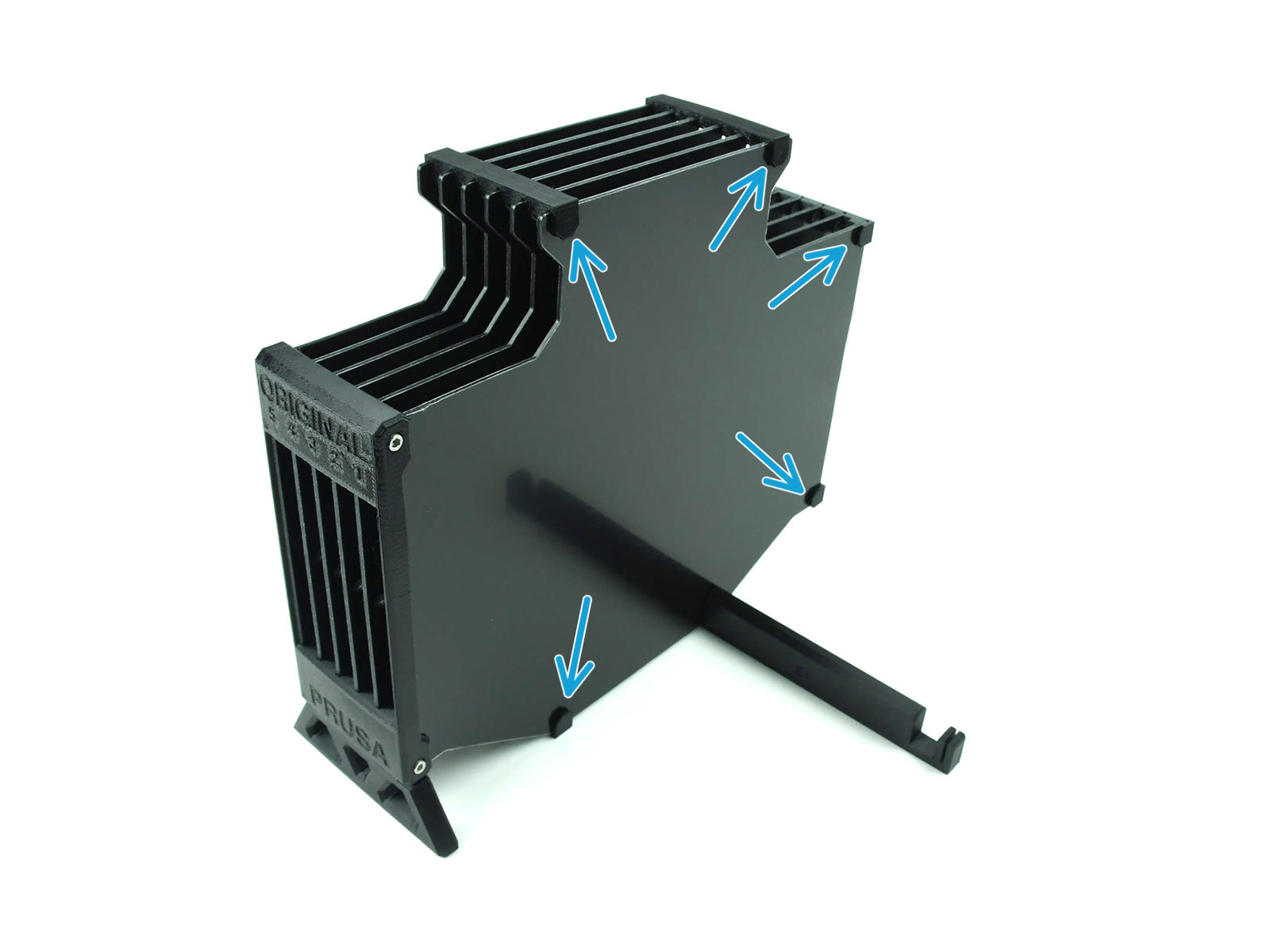

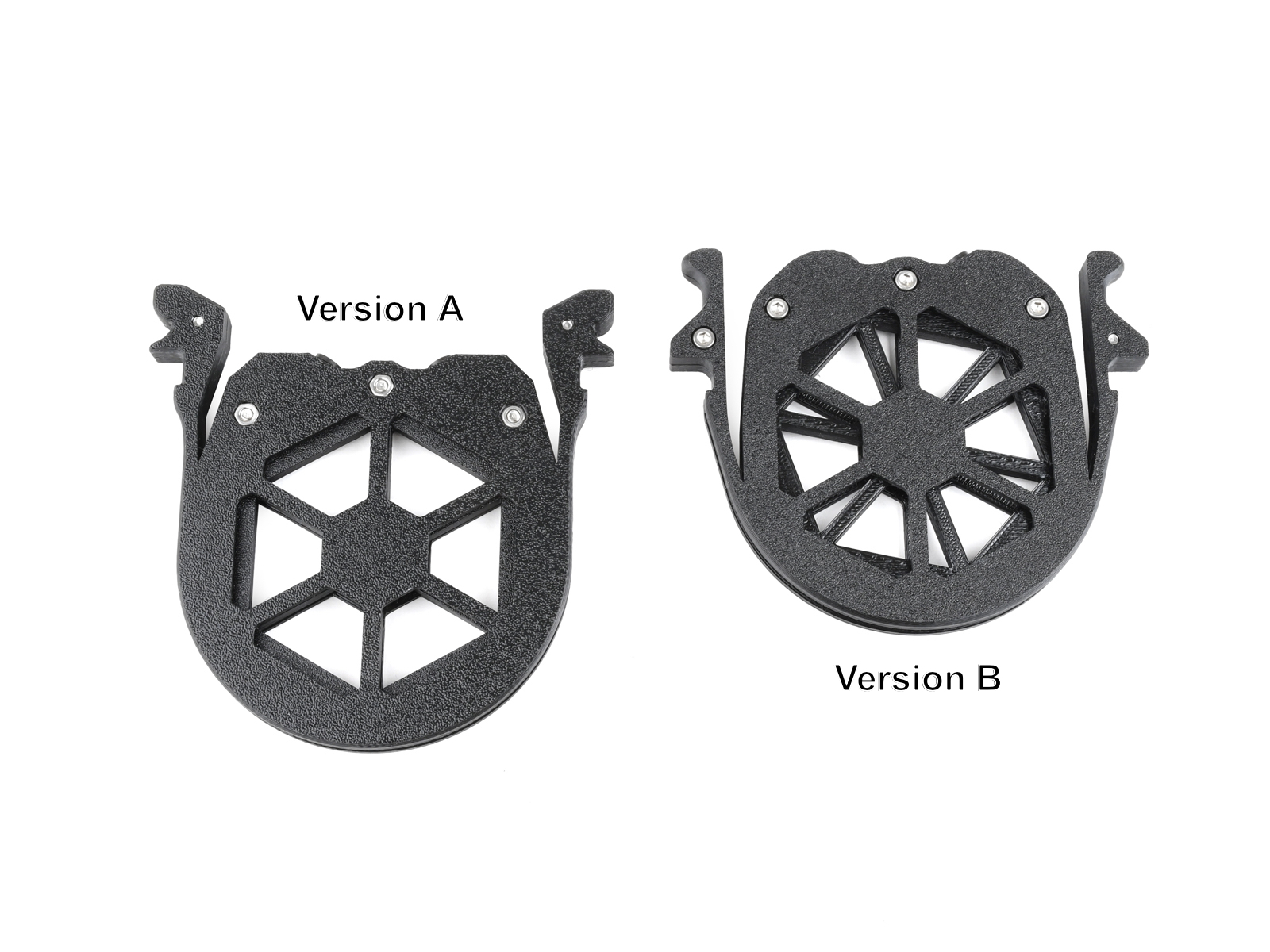

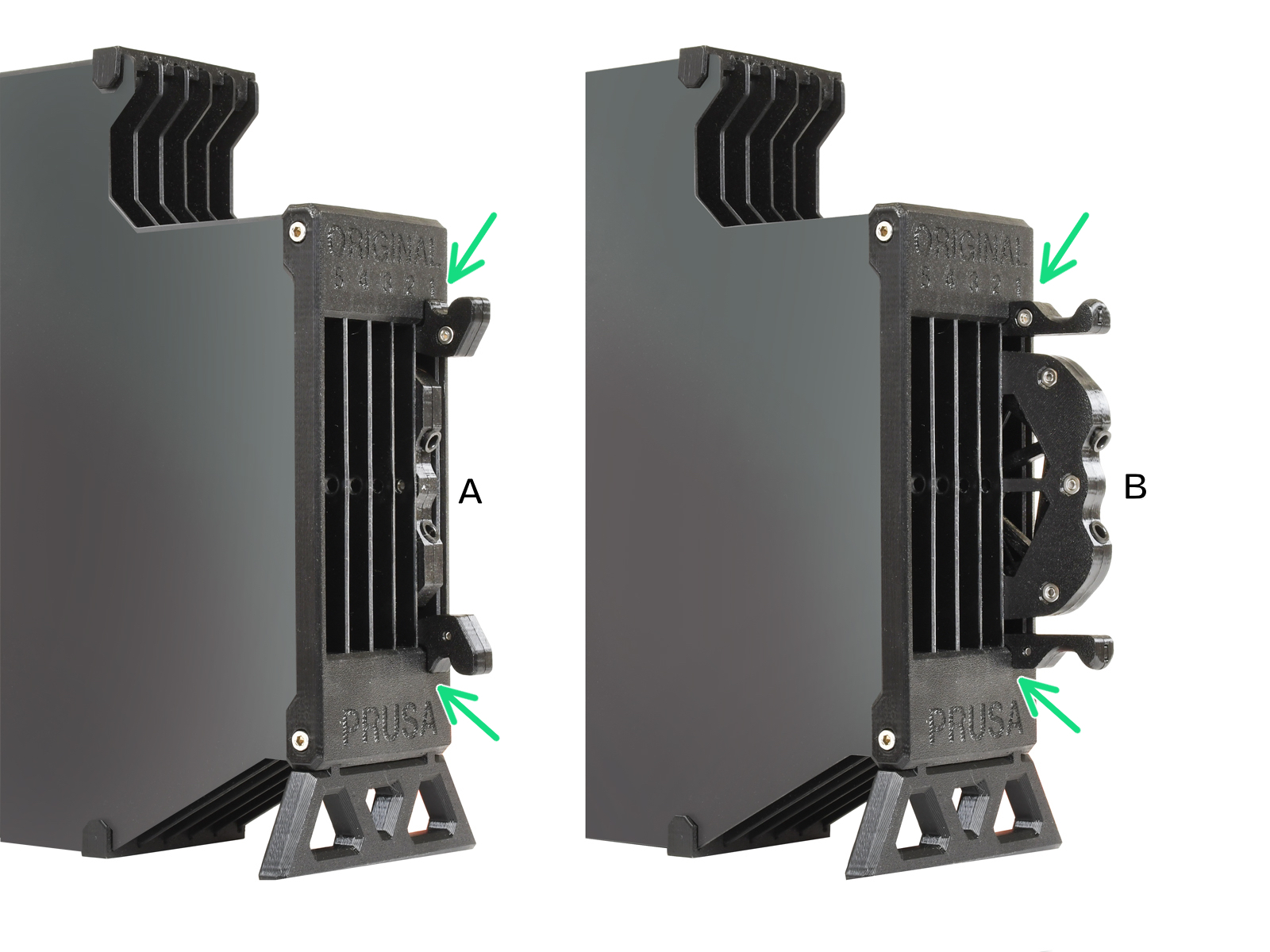

The MMU3 for the MK4 printer necessitates the use of the most recent buffer cartridge design, Version B.

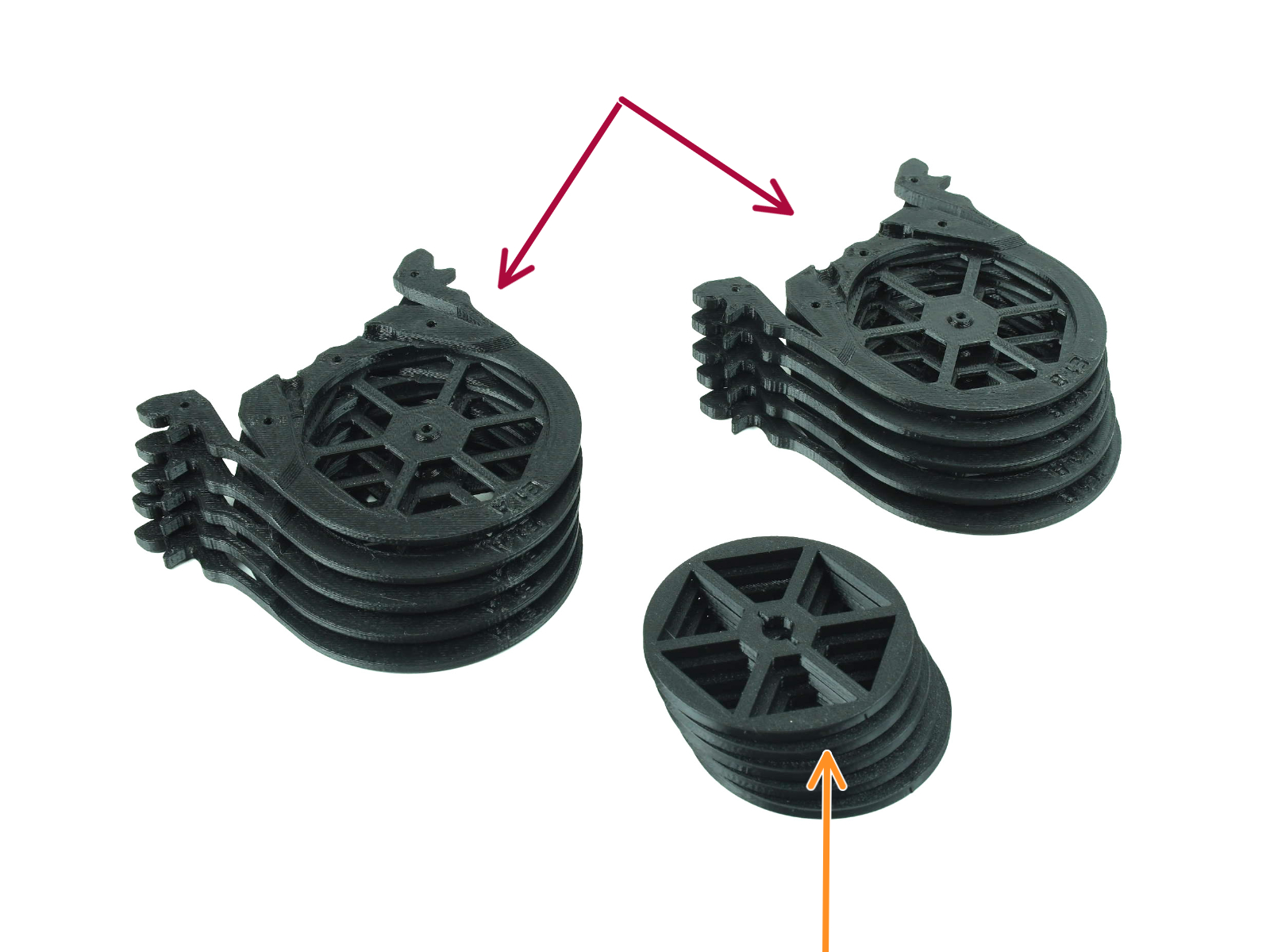

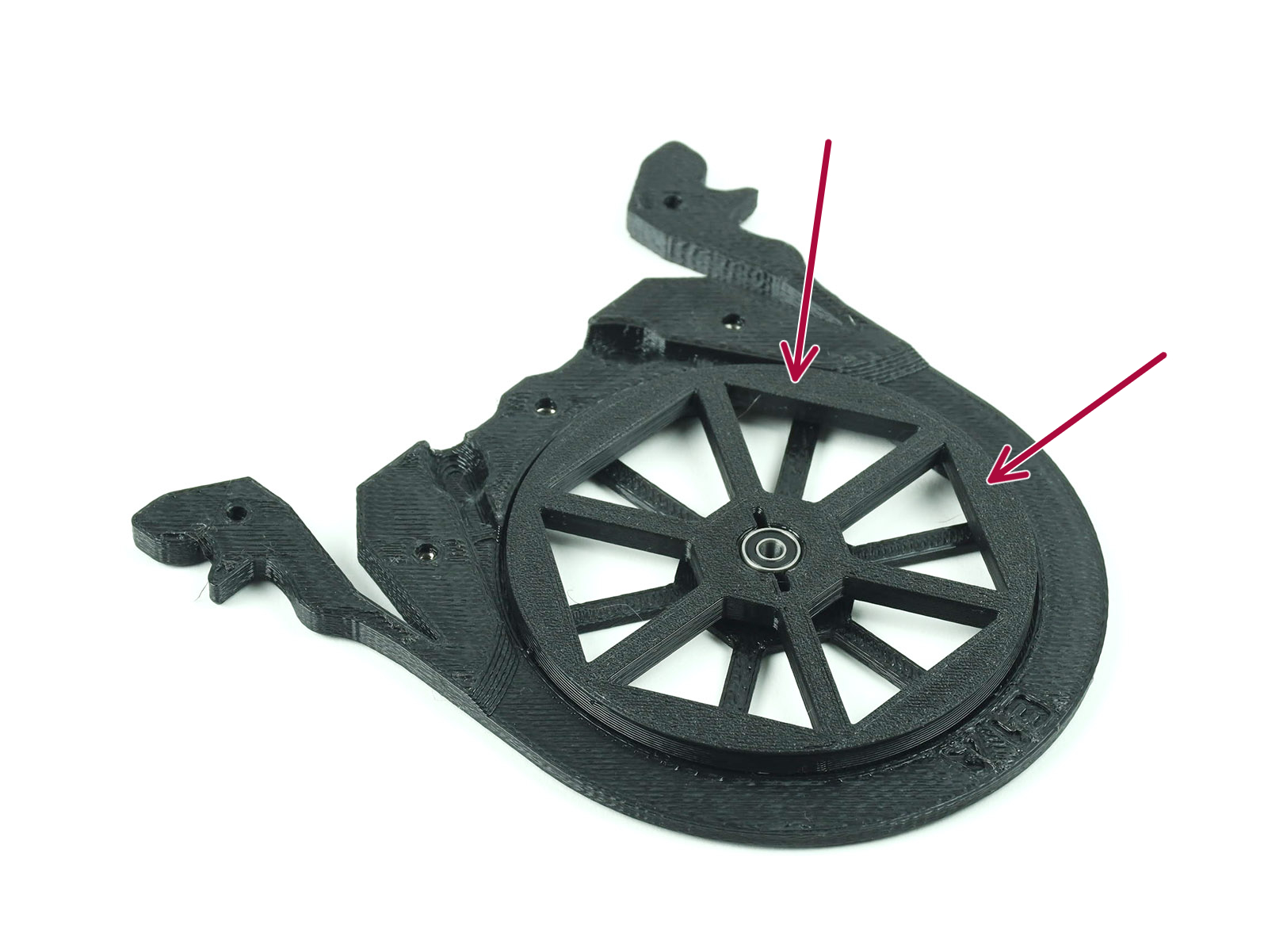

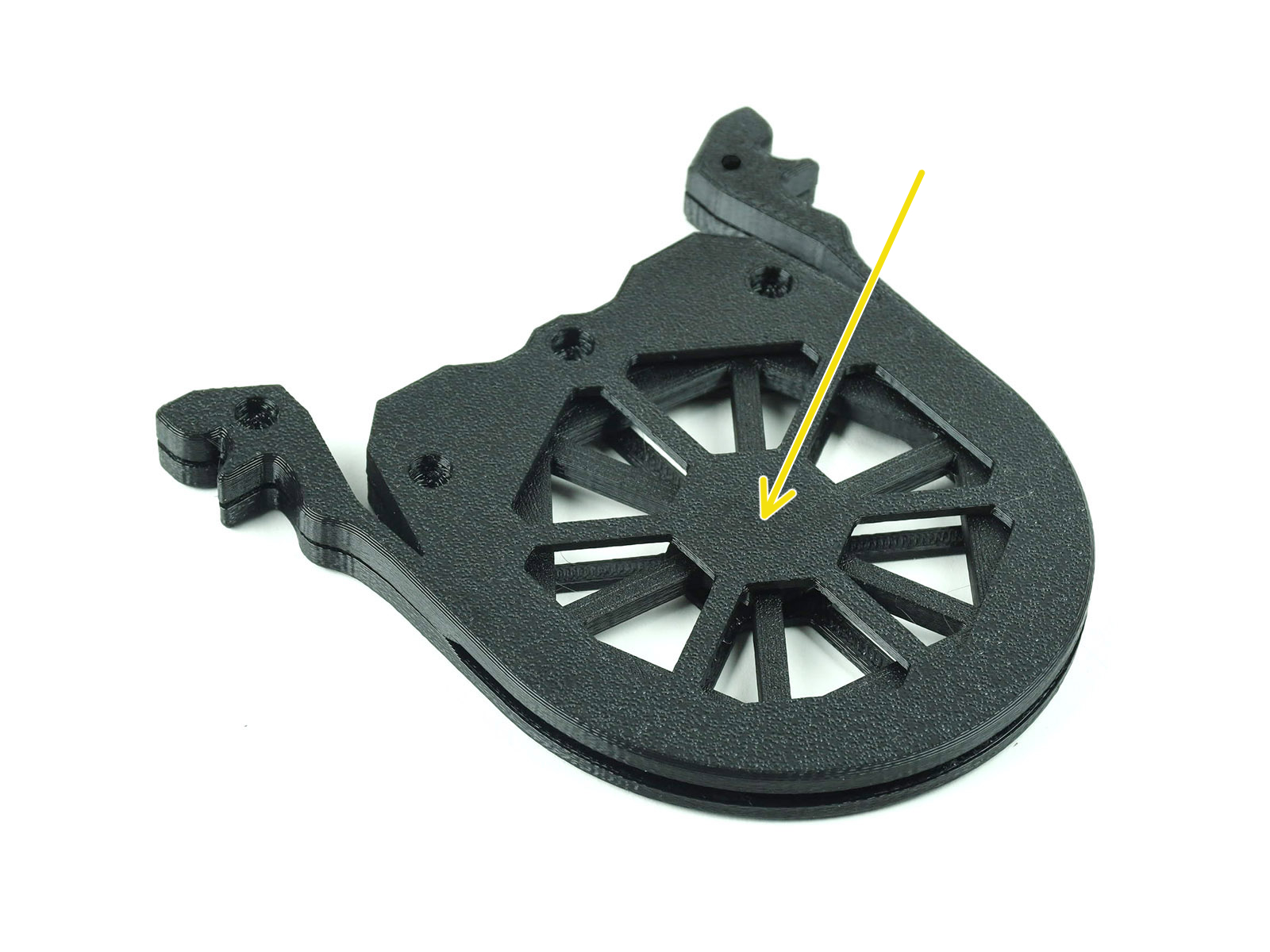

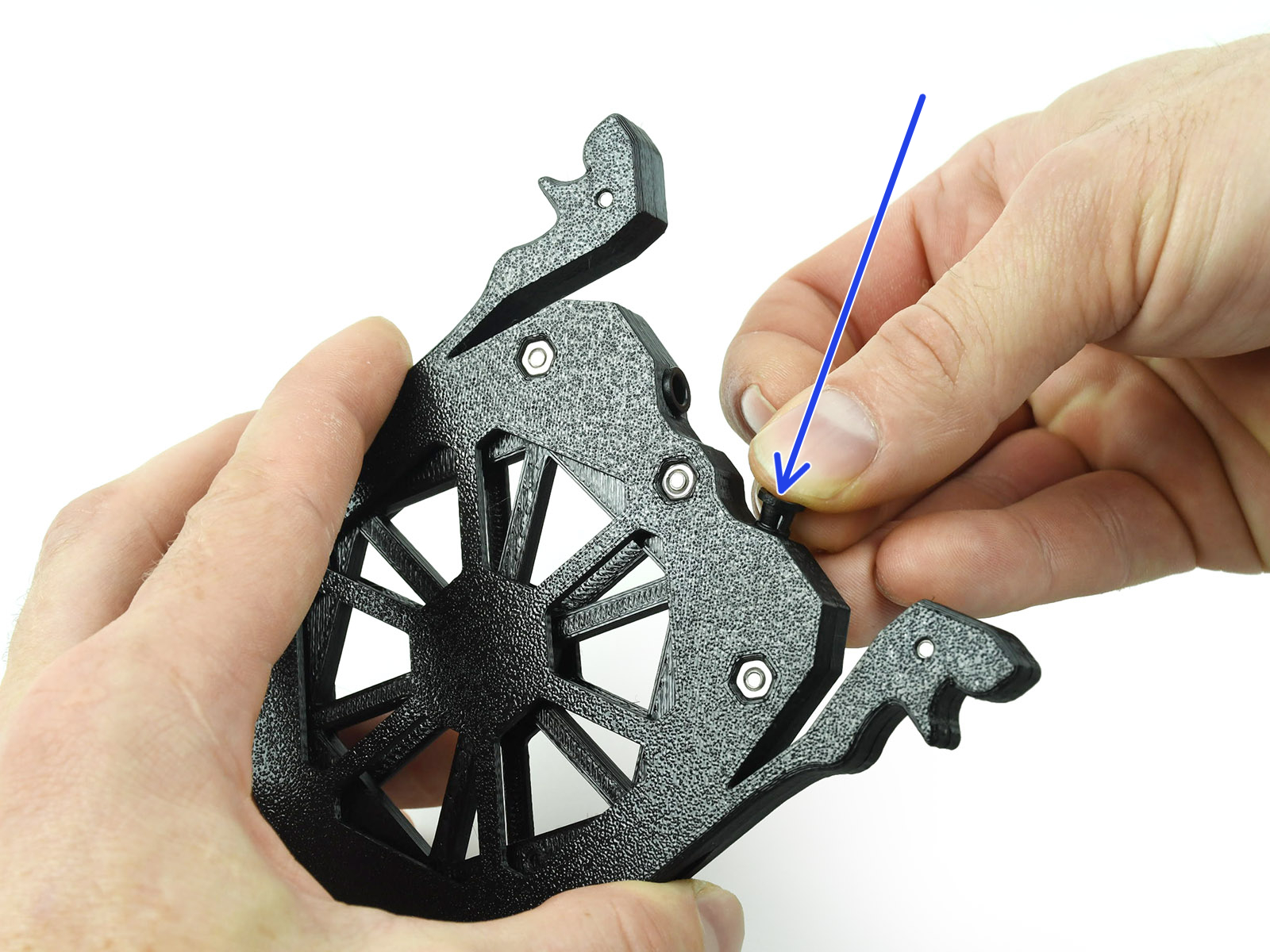

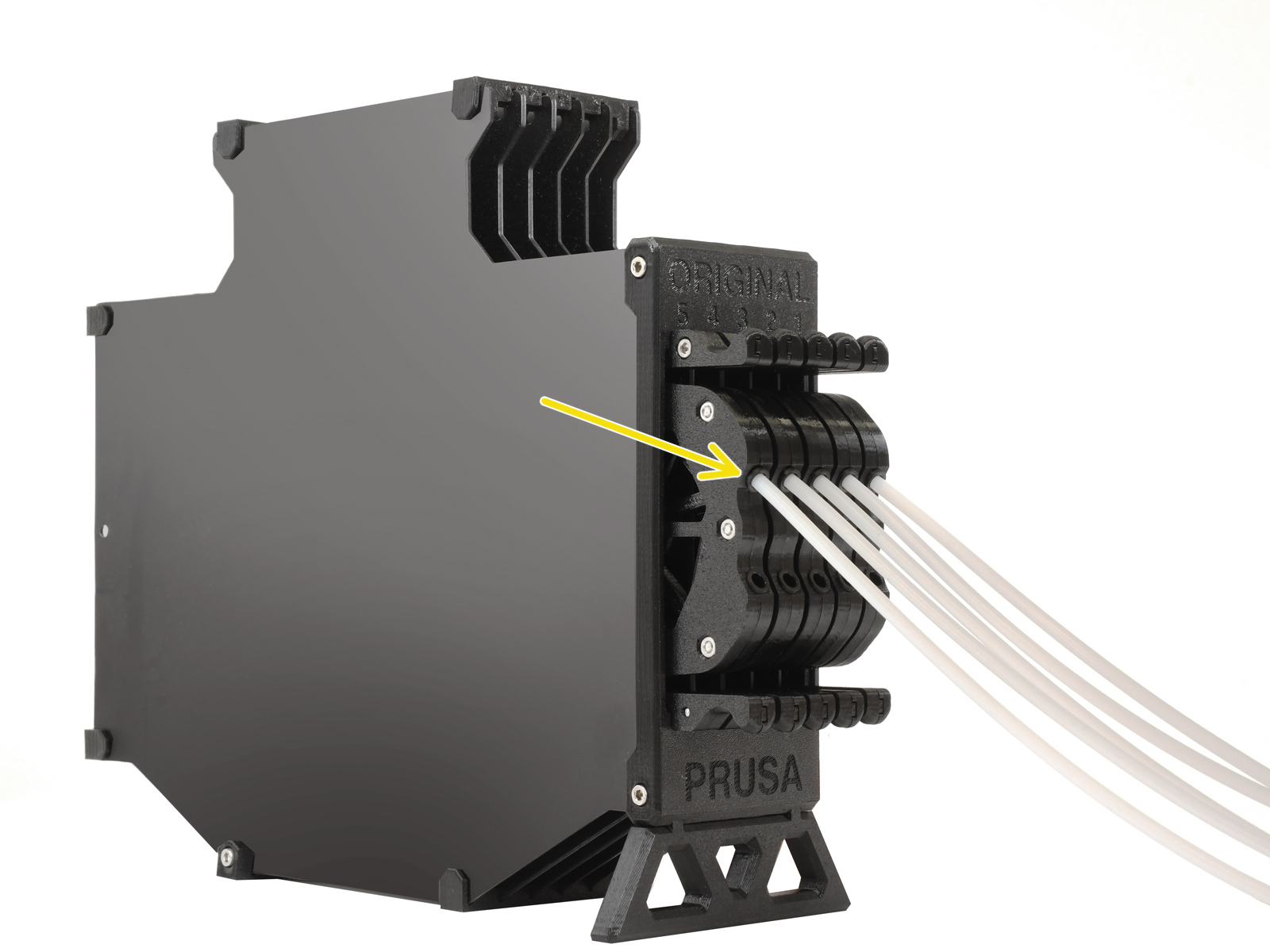

Insert the bearing into the center opening in the wheel.

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.