Starting accidentally another action during the print (e.g. XYZ calibration, switching sheet profiles, ...) can cause damage to the printer. This is why during the entire printing phase most of the menu items are unavailable. The safety of the user and the printer is the biggest priority.

However, some parameters can be adjusted (e.g. temperatures, flow, sound mode, ...) and those are shown in a special list called "Tune menu". The list differs from printer to printer and is expanded based on the new features and customer feedback.

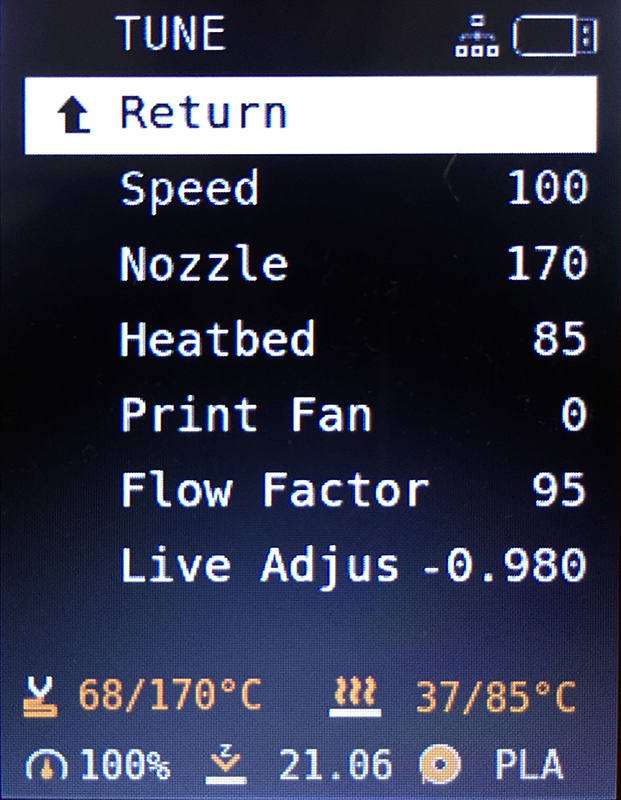

Example of the "Tune menu" on the MK3S:

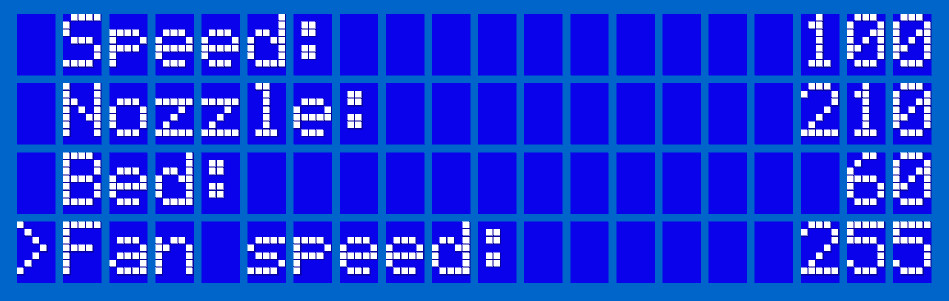

Example of the "Tune menu" on the MINI:

|

Was this article helpful?

This action is available only to registered users. Please log-in.

6 comments