- Čeština

- Español

- Italiano

- Deutsch

- Polski

- Français

- 日本語

- Home

- About your printer

- Printer features

- Filament sensor (MK4, MK3.9, XL)

Filament sensor (MK4, MK3.9, XL)

- Printer description

- Printer features

- Accelerometer (MK4/S, MK3.9/S)

- Brightness adjustment (SL1)

- Buddy firmware-specific G-code commands

- Cancel Object (MK4/S, MK3.9/S, XL, MINI/+)

- Crash detection

- Crash dump

- Creating a resin calibration object (SL1/SL1S)

- Dump memory (MK3/S/+ and MK2.5/S)

- Experimental menu (MK3/S/+)

- Experimental settings (MK4/S, MK3.9/S, MK3.5/S, XL, MINI/+)

- Filament sensor (MK4, MK3.9, XL)

- Check assembly

- How to clean the filament sensor

- Filament sensor MK3 (non-S)

- Flashing custom firmware (MK4/S, MK3.9/S, MK3.5/S)

- Flexible steel sheets (guidepost)

- GPIO Module

- High flow print head (HT90)

- High temperature print head (HT90)

- HW setup (MINI/MINI+)

- HW setup (MK2.5/S & MK3/S/+)

- Internet connection (SL1/SL1S)

- IR Filament Sensor (MK2.5S, MK3S/+, MK3.5/S)

- IR Filament sensor detection (MK3S)

- LCD brightness adjustment (MK3S)

- LCD screen contrast adjustment (i3)

- Loadcell (MK4/S, MK3.9/S, XL)

- Menu structure (SL1/SL1S)

- MMU3 Prusa Nozzle vs. CHT nozzle

- Model preview

- Network Connection (MK4S, MK3.9S)

- Nextruder silicone sock (XL, MK4, MK3.9)

- NFC antenna

- Noisy filament sensor (MINI)

- One-click print

- Pouring resin and starting print

- Power Panic

- Power-modes

- Print Profile (SL1/SL1S)

- Print statistics

- Printer statistics and system information (SL1/SL1S)

- Pronterface and USB cable

- Prusa firmware-specific G-code commands

- Prusa Pro Filament Drybox

- Resin Calibration (SL1/SL1S)

- Resin Tank Cleaning (SL1/SL1S)

- Satin steel sheet

- SD card sorting

- Smooth Steel Sheet

- Sound mode (MINI/MINI+)

- Special PA Nylon steel sheet

- SpoolJoin (MMU2S)

- Steel sheet profiles

- Stuck filament detection #26101 (MK4S) #13101 (MK4) #21101 (MK3.9) #17108 (XL)

- Support menu (MK3/S/+)

- Support settings for the XL

- Textured steel sheet

- Thermal model calibration

- Tools Mapping (XL)

- Tools Mapping and Filament Mapping (XL, MMU3)

- Top-bar Notifications (SL1/SL1S)

- Touch screen (MK4/S, MK3.9/S, MK3.5/S, XL)

- Tune Menu

- Water-soluble materials (PVA/BVOH)

- General Information

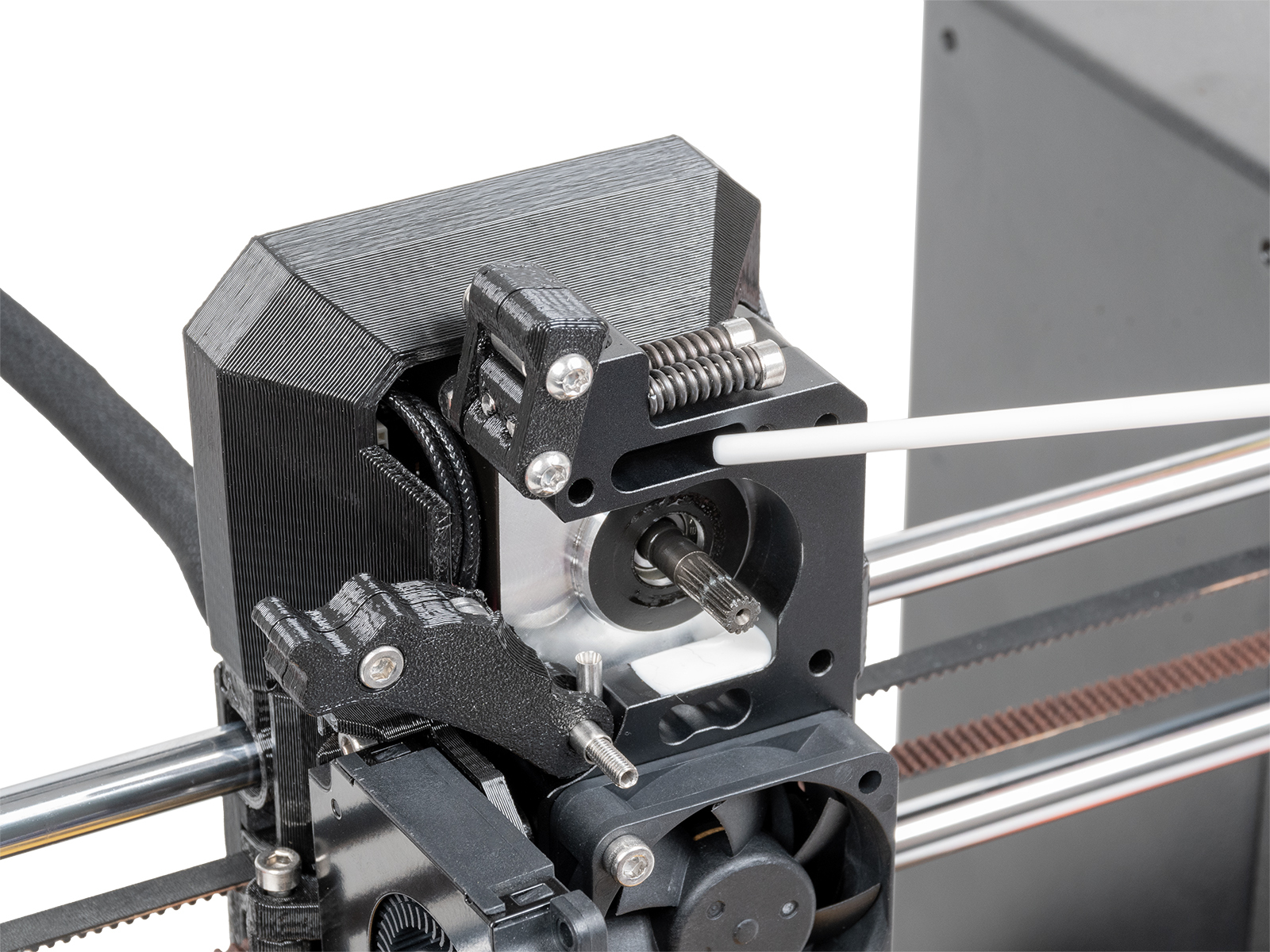

The filament sensor equipped on the Original Prusa MK4, Original Prusa MK3.9, and each tool of Original Prusa XL detects the presence of a filament and filament run-out. The sensor is a Hall sensor, triggered by a mechanism composed of a spring, a magnet, and a ball.

Check assembly

If your printer is a kit, you have received a package with magnets for the assembly. Note that two magnets are sent, but one is meant to be used in the assembly, and the other is a spare. If your filament sensor does not work, check if two magnets have not been added by accident.

|  |

How to clean the filament sensor

During usage, filament residue might build up around the sensor or its mechanism, possibly causing false readings and thus malfunctioning.

1) Compressed air

At the top of the extruder is a small hole, insert the tip of a compressed air can in the hole. With your free hand, prepare a bit of filament with a non-stringy tip. Repeatedly insert and remove the filament from the extruder, while blowing the compressed air. This will dislodge the build-up debris.

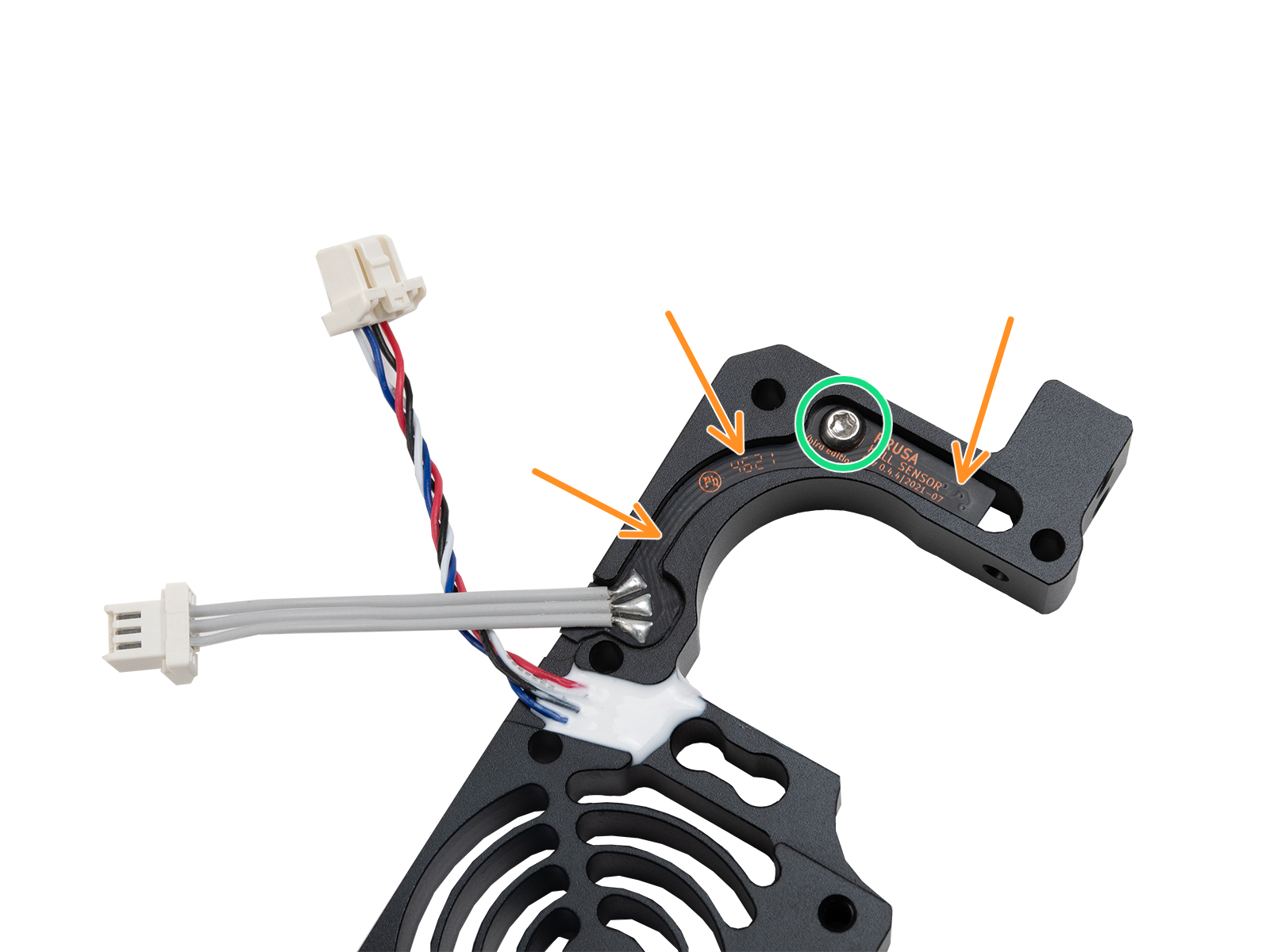

Top view of the MK4 print head. The XL print head has a similarly positioned small hole.

Top view of the MK4 print head. The XL print head has a similarly positioned small hole.

2) Filament tip insertion

In case you don't have compressed air at hand, a similar procedure to the one above can be attempted.

Prepare a bit of filament with a non-stringy tip. Repeatedly insert and remove the filament from the extruder. It will be necessary to insert and remove the bit of filament several times to achieve good cleaning, and the technique might not always be effective.

3) Removing the sensor (MK4, MK3.9)

PG-assembly-adapter printed with MK4

PG-assembly-adapter printed with MK3/S/+

If the previous techniques do not work, the filament sensor can be removed to be manually cleaned. This procedure requires partial disassembly of the E-axis.

- Unload the filament, then wait for the printer to fully cool down. After that, turn the printer off.

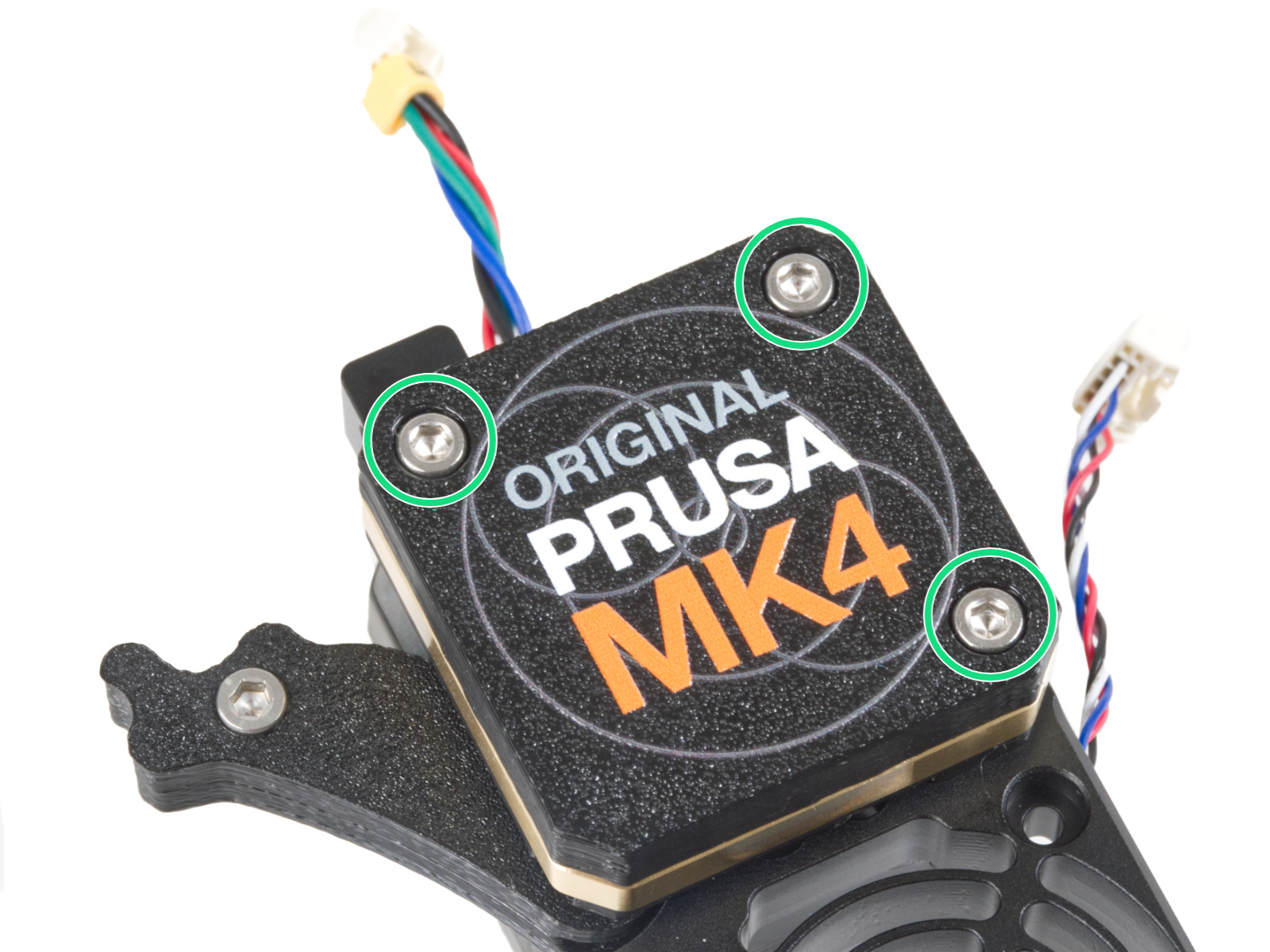

- Remove the PG-case, together with the PG-ring, gearbox, and main plate. Remove all of these parts in one piece.

|  |

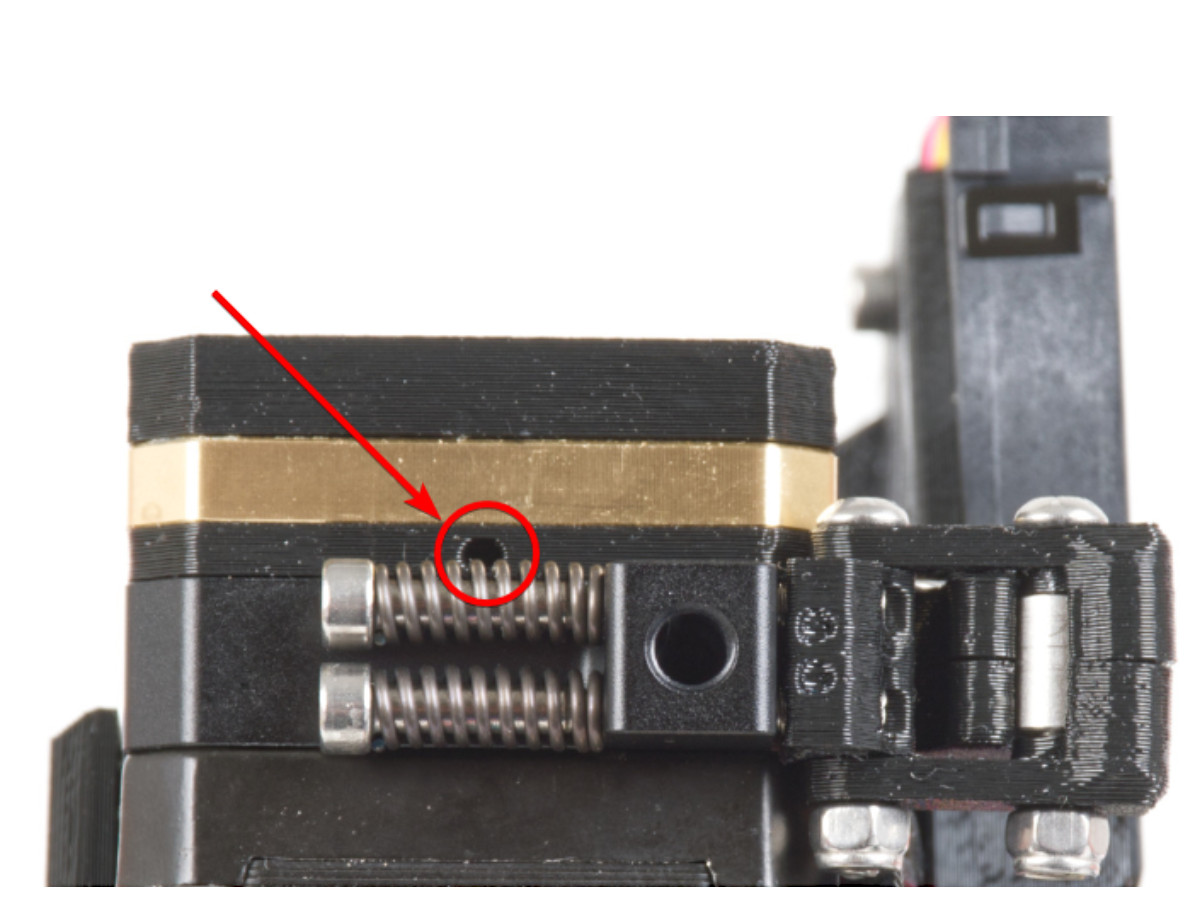

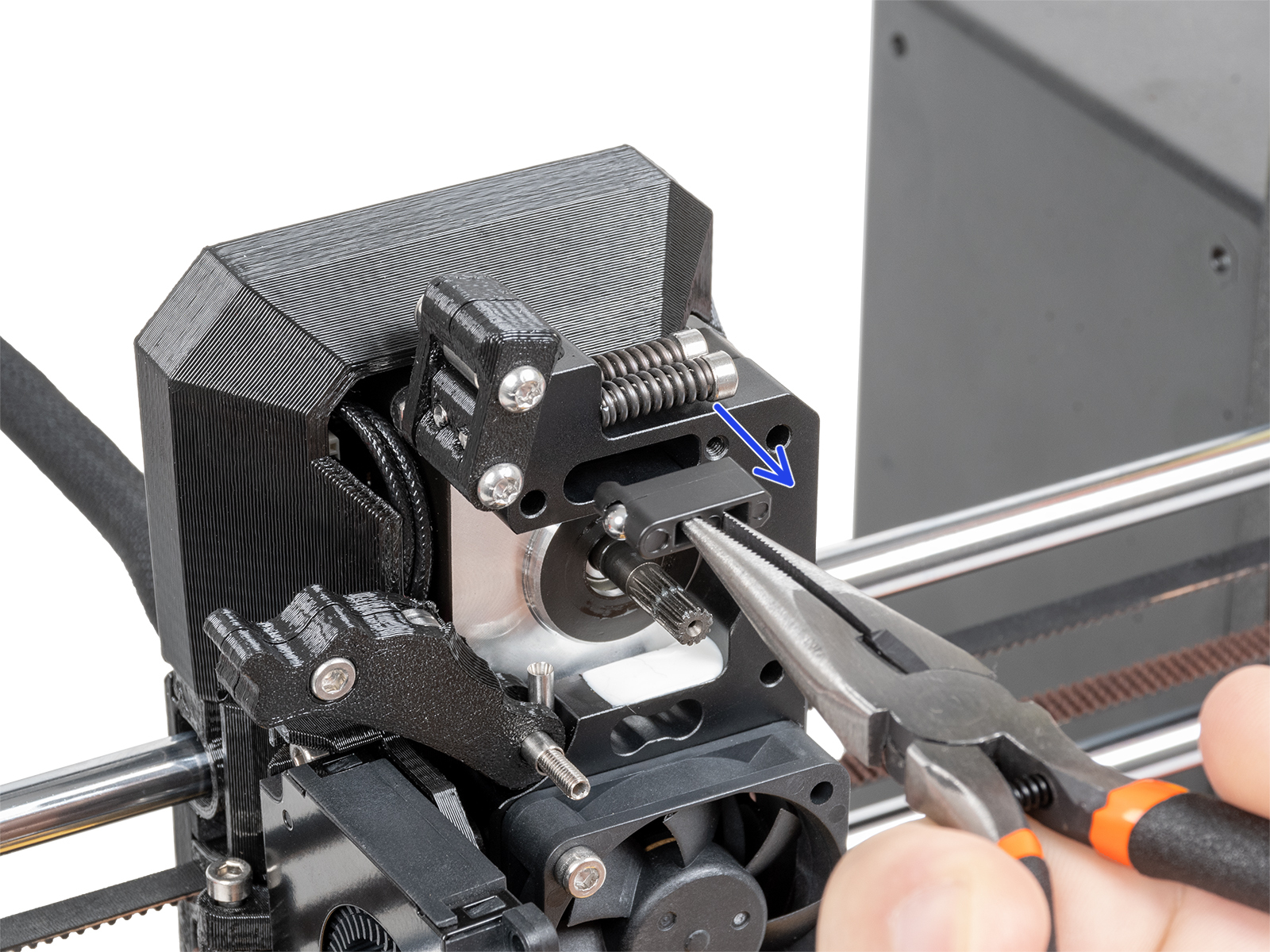

- Remove the Prusa-ball-holder using pliers.

- Carefully remove the ball-magnet-spring combo from the Prusa-ball-holder and clean any debris out of it. Clean also the slot on the heatsink.

|  |

- Reassemble the Prusa-ball-holder in the following order: steel ball, magnet, and spring.

- Reassemble the block with PG-case, PG-ring, gearbox, and main plate.

Comments

Still have questions?

If you have a question about something that isn't covered here, check out our additional resources.

And if that doesn't do the trick, you can send an inquiry to [email protected] or through the button below.