If this occurs it indicates a problem with the P.I.N.D.A. or SuperPINDA sensor. P.I.N.D.A. stands for Prusa INDuction Auto leveling. It is the Z-axis end-stop on the MK2/S and MK3/S. It accurately detects metal within a certain range, so if the nozzle crashes into the bed the P.I.N.D.A. is either adjusted too high in relation to the nozzle, or the sensor itself or its cable may be faulty.

Testing the P.I.N.D.A./SuperPINDA sensor

If the P.I.N.D.A. sensor, or more commonly any of its wires, is damaged there can be multiple different leveling issues. Please see P.I.N.D.A./SuperPINDA Sensor testing for more information.

Lowering the PINDA

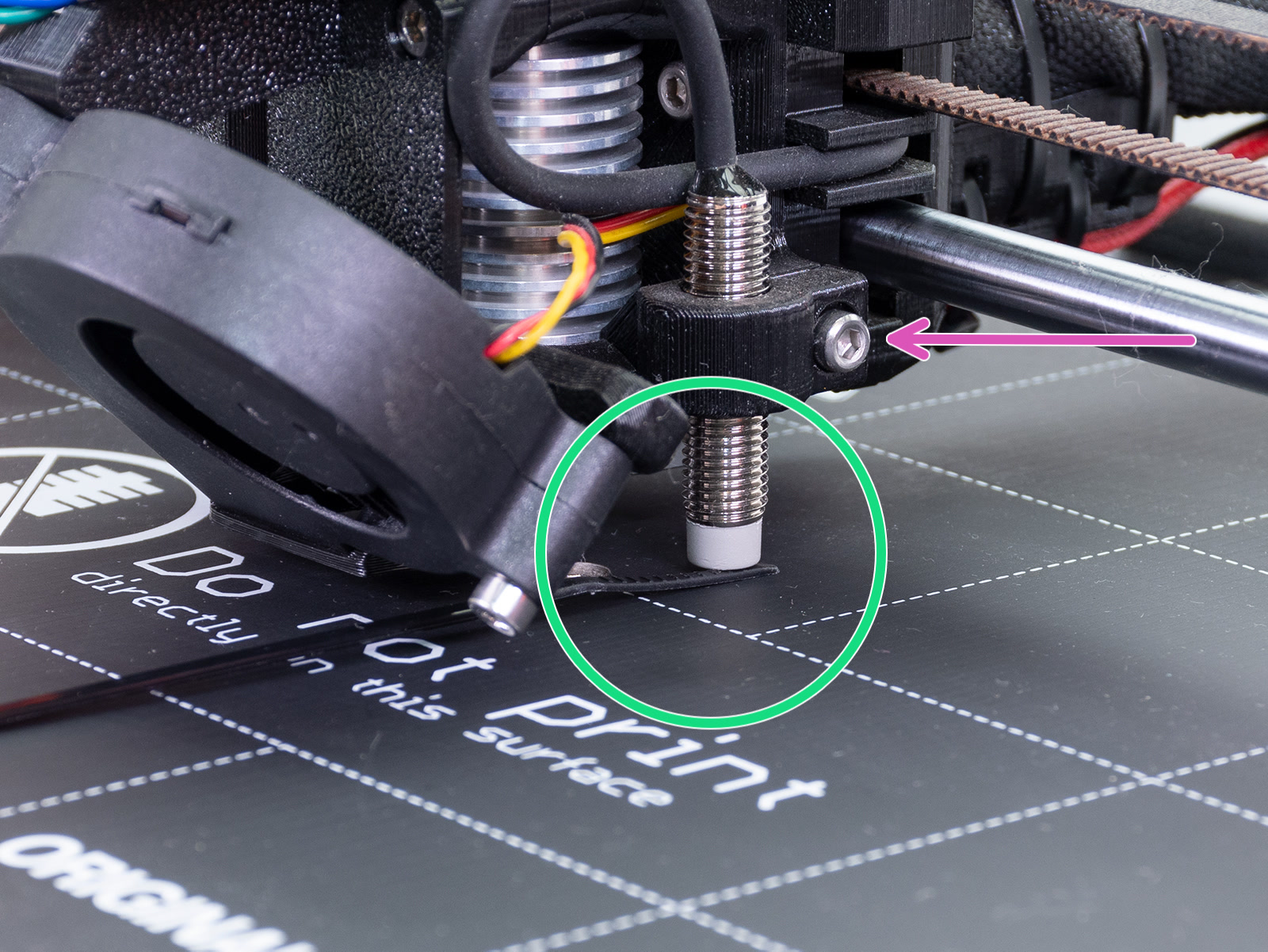

The P.I.N.D.A./SuperPINDA holder is closed by a screw marked by the purple arrow in the picture below. In order to change the height of the sensor, open this screw.

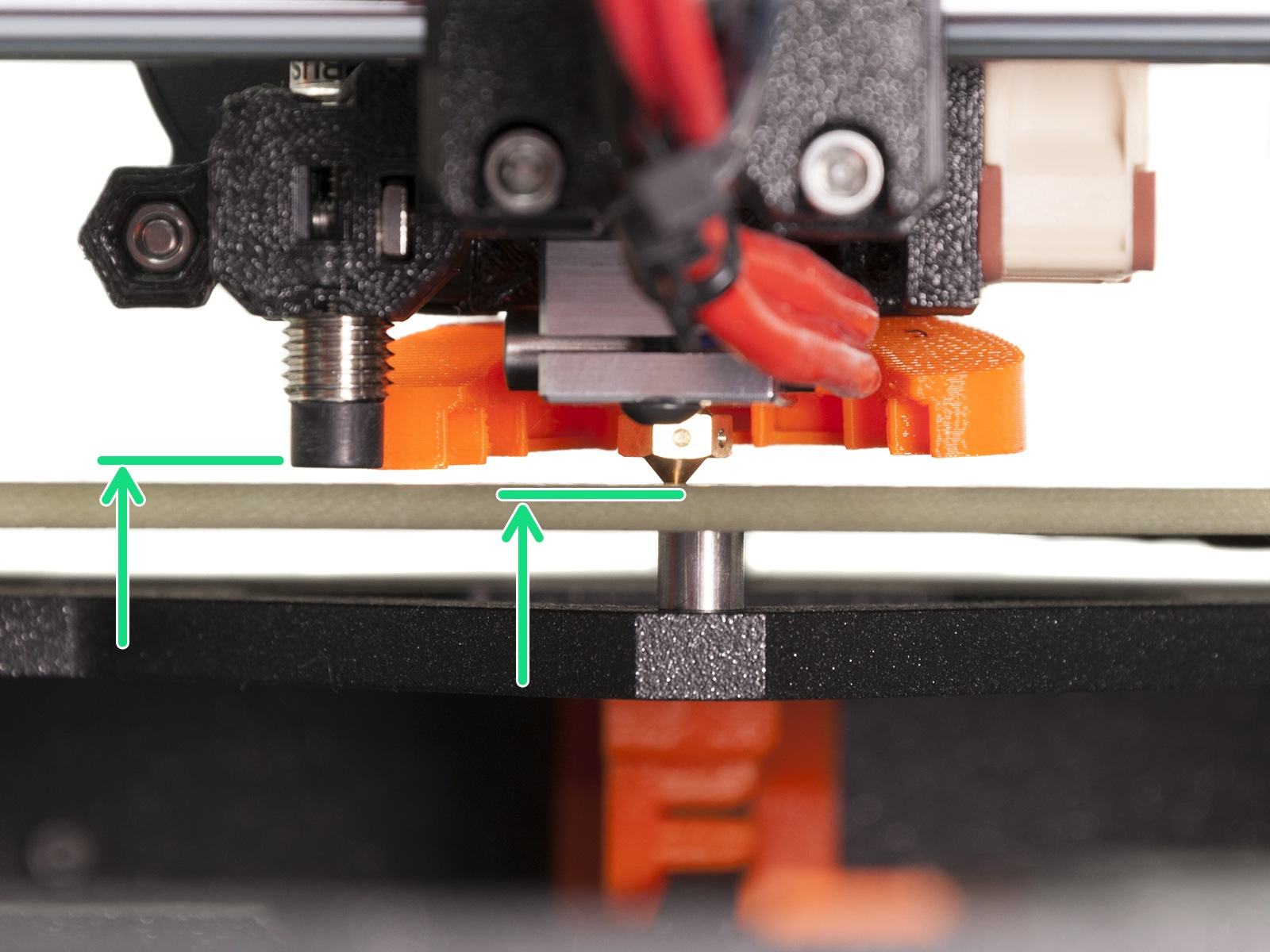

Lower the P.I.N.D.A. sensor by 1-2 threads, or redo the pre-flight check, where you use the thin tip of the zip-tie instead of the thicker center which is instructed (circled in green in the picture below).

Make sure to tighten the holder screw after adjusting the height.

2 comments

THANK YOU

Hi! Oh yes, the smooth sheet is a bit thicker! First layer calibration for both the textured and smooth profiles in HW setup should be enough to compensate for the difference if PINDA height is set according to the manual.